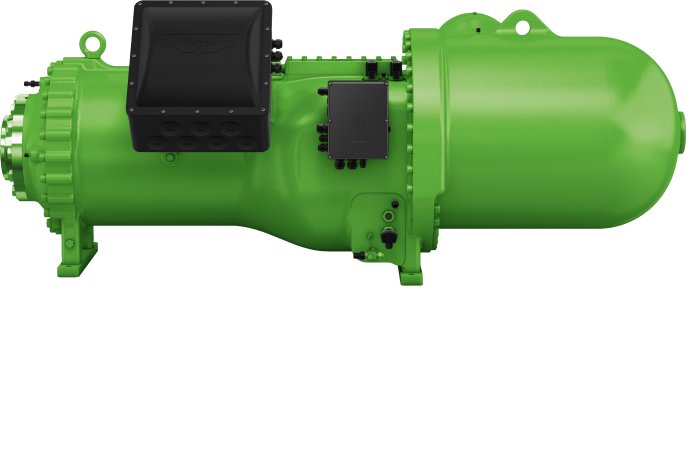

The efficiency requirements for liquid chillers are constantly rising. This is the case in China, Europe and the United States. The compressor takes on a particular role, as the heart of the system. The CSW105 series is the latest addition to BITZER’s range of established CSW compact screw compressors for efficient use in liquid chillers. They were specially developed for low liquid temperatures and meet the energy-efficiency grade 1 requirements of the Chinese regulation GB19577:2015 as well as the minimum energy performance standards (MEPS) of the EU. BITZER optimised the new rotor profile for R134a and alternative HFO refrigerants. The integrated IQ module CM-SW-01 enables cost-efficient integration into existing systems and efficient, secure operation in the extended map.

Designed for maximum efficiency

The CSW compressor series is setting new standards in energy efficiency in full- and part-load operation. Thanks to their slider control, the compact screw compressors achieve a particularly high level of efficiency at loads of 60 to 100 per cent. At the China Refrigeration 2017 trade fair, BITZER will present its new range of high-efficiency, easy-to-use compressors in the form of the CSW105 series, specially designed for operation with refrigerants with low GWP (global warming potential). The new CSW105 screw compressors are suitable for use in water cooled liquid chillers and in air cooled liquid chillers at moderate ambient temperatures. They can be used in liquid chillers for cooling and heating as well as for low-temperature heat pumps. They are very versatile due to their compact design and the minimal weight of their class.

BITZER is planning to launch the new compact screw compressors in four different models. They will offer displacement of 1,120 m3/h to 2,000 m3/h (at 50 Hz operation). For example, the largest CSW105, the first compressor in the range to be launched, with a displacement of 2,000 m3/h in conjunction with R134a (at an operating point of 5°C/38°C and 50 Hz operation) can achieve a cooling capacity of 1.4 MW. This corresponds to double the capacity of the largest compressor model at the present time, the CSW95113. The usage limits were extended for higher evaporation temperatures, so as to enable more efficient cooling of data centres, for example.

Intelligently controlled

The new CSW105 compact screw compressors from BITZER offer the efficient, infinitely adjustable capacity control CR (capacity regulation). The optimised slider concept for automated Vi adjustment also regulates the volume ratio independently and efficiently in a wide range of applications. The integrated IQ module CM-SW-01 with prewired sensors and actuators enables the compressors to be easily integrated into the system controls. The intelligent module then operates built-in features such as slider positioning and slider position detection or switches on oil heating if necessary. The CSW105 compressors thus adapt optimally to operating conditions and offer maximum efficiency, safety and reliability. Comprehensive monitoring and recording options as well as potential remote operation via the BEST software from BITZER make operation and maintenance even simpler.

Strong with low-GWP refrigerants

The improved full- and part-load efficiency of the CSW105 series enables OEM users to develop liquid chillers which meet the highest international energy-efficiency standards in China, Europe and the United States. A wide range of compatible refrigerants ensures flexibility and investment security. The new compact screw compressors were designed for operation with the refrigerant R134a which is highly efficient in climate applications. They are also HFO-ready and are suitable for the HFO substitutes R1234ze(E) and R1234yf. The latter have a GWP of less than 10. The two HFOs are suitable for air conditioning and medium-temperature applications in particular, as well as for heat pumps. The HFO/HFC blends R513A and R450A are also approved for the CSW105 compressors. With a GWP of around 600, they are still part of the A1 safety group.

Simple and compatible

Integrated thermal monitoring for the suction gas-cooled built-in motor simplifies system integration. With their integrated oil separator, the CSW105 compact screw compressors can also be integrated into direct expansion systems, or they can be used as primary oil separators in systems with flooded and diesel evaporators. The externally accessible oil filter makes service easier.

Other stand-out features of the CSW105 series include redeveloped rotor profiles for improved volumetric and isentropic compressor efficiency, robust axial and radial shaft bearings with large support areas for reduced bearing loads, an integrated check valve and qualification for operation with an external frequency inverter.

Overview of images

Images may only be used for editorial purposes. This usage is free of charge if "Photo: BITZER" is given as the source and a complimentary copy is forwarded to us. Changes to the images – apart from cropping to the main motif – are not permitted.