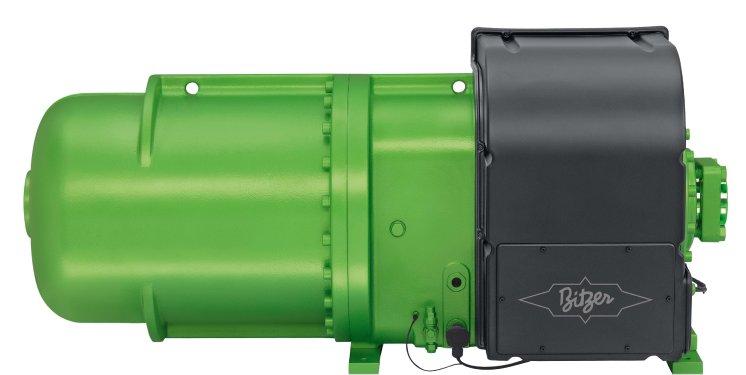

The CSVW2 technology study has been specially designed for use with water-cooled liquid chillers in installations with low condensing temperatures. Its mechanism is based on the tried-and-tested CSVH2 compact screw compressor, thus combining proven strengths with new capabilities at low load conditions. In order to achieve a high COP for this application, and thus also attain a good ESEER, BITZER has integrated some innovative drive technology. This is particularly important in chillers using water-cooled condensers. The CSVW2 study pulls off this trick by devising a new permanent magnet motor which delivers better efficiency at low speeds and low loads than the CSVH series. As a consequence BITZER has even modified the frequency inverter.

Water-cooled chillers

Unlike the CSVH2 compressor, the CSVW2 has been optimised for water-cooled rather than air-cooled chillers. To this end BITZER has adapted the familiar mechanism of the CSVH2 compact screw compressor to these new operating conditions, thereby bringing on board for the CSVW2 the CSVH2’s strengths such as durability and wide application range, from process cooling to heat pump applications. The CSVW2 study also features automatic operating parameter control and a performance range which can be reduced by up to 16 per cent. The CSVW2 study is the same size and weight as the compact CSVH2 range. Thus the CSVW2 will not only set new efficiency benchmarks for its class but also offer the lowest weight and most compact dimensions.

Volker Stamer, BITZER Director Sales Stationary Products notes that “the CSVW2 compact screw compressor study opens up new application options for OEMs, thus expanding the BITZER portfolio. Combining proven technology and innovative strength is the secret of our success”.