‘Refrigeration and air-conditioning technology is very important in India’, explains Rob de Bruyn, Managing Director of BITZER Refrigeration Asia. ‘In vast regions of India, which is second only to China in terms of population, the climate is sub-tropical or tropical. Intact cooling chains are therefore crucial for transporting fresh food to its destination. In 2014 we will present our comprehensive range of products at the India Cold Chain Show. With the reliability and quality of BITZER, we will be able to provide a great deal of support to the people on site whilst benefiting from the opportunities for growth in India.’

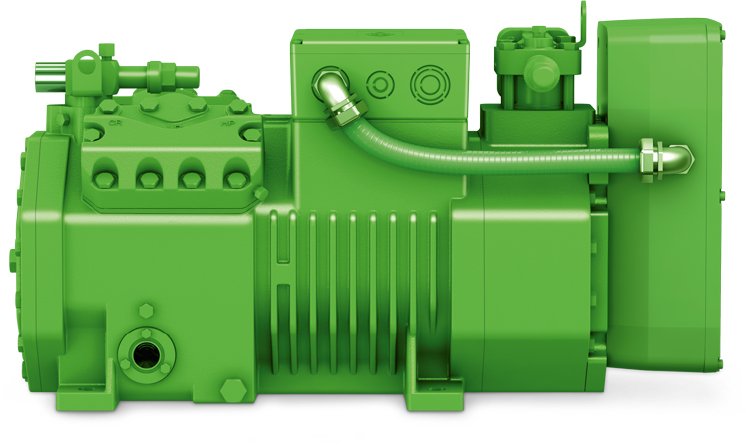

Infinitely adjustable cooling capacity – the ECOLINE VARISPEED

ECOLINE VARISPEED reciprocating compressors offer high cooling capacity and reliability, as well as excellent energy efficiency. With their internal frequency inverters, the speed control can be infinitely adjusted to suit the operating conditions perfectly. This minimises suction pressure fluctuations and cycling rates, which in turn reduces operating costs. The ECOLINE VARISPEED does not require regular maintenance or a fan as the suction-gas-cooled operating elements ensure that the temperature of the electrical components remains optimal.

Efficient: ORBIT scroll compressors

Efficient, reliable and best suited to air-conditioning systems and heat pumps – this is the series of ORBIT scroll compressors from BITZER. They offer a high isentropic efficiency and are highly energy-efficient under both full and part-load. ORBIT compressors are available in two case sizes, the ORBIT 6 and ORBIT 8. The displacement of the ORBIT scroll compressors ranges from 20 to 77 m3 per hour (50 Hertz). Other advantages of the ORBIT series are their low sound levels, wide range of applications and the innovative oil management system BAHT. The patent-pending BITZER Advanced Header Technology (BAHT) is designed for scroll compressor tandems and trios and makes it easier to combine even or uneven compressor sizes in a parallel circuit in air-conditioning and heat-pump systems. The newly developed suction gas header with integrated oil distribution plays a key role in this improvement, directing oil to one of the compressors in the tandem and trio units – and from there distributing it among the other compressors.

Compact performance – the ECOSTAR

The ECOSTAR is one of the highlights of the India Cold Chain Show. The compact, air-cooled condensing unit is distinctively energy-efficient and compatible with a wide range of applications. The cooling capacity of the BITZER ECOSTAR can be adjusted to best suit the actual requirements thanks to the speed control of the compressor and condenser fan. Precise temperature control increases the efficiency of the refrigeration system and reduces operating costs. The internal control enables quick and easy installation of the condensing unit.

Optimised for the high ambient temperatures in India – LH265

Another BITZER highlight at the India Cold Chain Show will be the air-cooled LH265 condensing units with semi-hermetic reciprocating compressors for universal applications. In its factories in Schkeuditz (Germany) and Jakarta (Indonesia), BITZER adapts the compact screw compressor units to suit the special operating conditions in India. This way, the LH265 condensing units run reliably and safely even with outside temperatures of up to 49°C. This makes them vastly superior to similar condensing units which exceed their maximum compressor operating parameters at just 43°C. LH265 condensing units are easy to install and quick to commission.

Green Point

The name BITZER stands for high standards; worldwide and for 80 years. To ensure that these quality standards are met, the refrigeration compressor specialist has been expanding its Green Point network in India since 2011. The project offers comprehensive maintenance and other services for compressors. The first Green Point in India opened in Delhi in March 2011, followed by others in Mumbai in November 2011, Bangalore in July 2013 and Kolkata in May 2014. ‘We have carefully selected the geographical locations of our Green Points’, explains Harvinder Bathia, Country Manager of BITZER India. ‘With branches in the north, west, south and east of India, we can be as close to our customers as possible. This shortens replacement times if a compressor should have to be repaired. As of October 2014 we have repaired around 1,800 compressors in our Green Points – quickly and reliably.’