The highlights from this company, which was founded in 1879, consist of compressor and system valves, FAS components and advanced accessories. Armaturenwerk Altenburg focuses on sustainability and provides solutions for the use of natural refrigerants. Today, the company provides a wide range of refrigeration and air conditioning products.

Visitors can visit the booth and see the solutions for the use of natural refrigerants such as NH3 (ammonia), CO2 (carbon dioxide) and propane for themselves. For example, of special note are the stainless-steel valves with diameters of 6, 10 and 12 mm that can withstand pressures of up to 160 bar, as well as stainless-steel valves designed especially for applications involving ammonia and pressures of up to 63 bar.

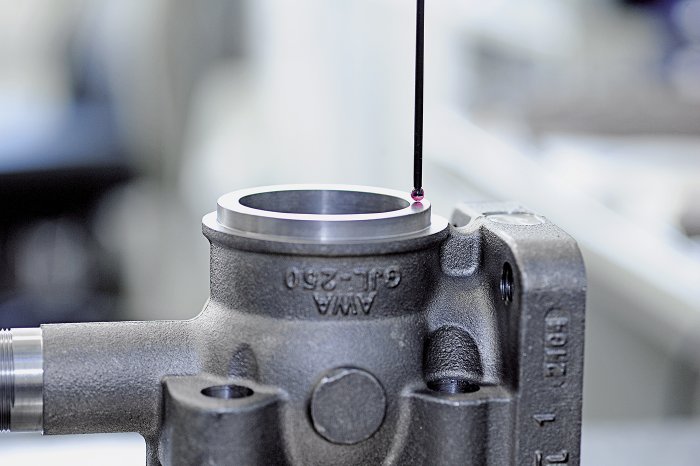

Additionally, AWA will present the FAS system valves that have been designed for a greater range of pressures of up to 60 bar. The brand has been complementing the range of Armaturenwerk Altenburg GmbH since 2002. The quality of AWA’s entire production is ensured as it manufactures with cutting-edge systems technology. For example, advanced three-dimensional design and analysis software is used to measure flow behavior.

Flexible valves

The valves, which consist of several components, enable connection to a number of compressors and use with almost all conventional refrigerants – including ammonia, propane and CO2. The standards of all AWA valves are always clear: optimal flow behavior, even under the most difficult conditions.

Armaturenwerk Altenburg also provides a wide range of accessories, including sight glasses. Using AWA fittings and adapters, different connections can be connected and all types of refrigeration system can be filled with ease.

“Armaturenwerk Altenburg is in an excellent position. This is reflected by our latest developments,” says Kai Kowalewsky, Managing Director of AWA. “We are therefore very happy to be presenting these to the public at Chillventa 2014.”

Advanced technology in production

AWA, based in Altenburg in Thuringia, relies on advanced technology for its innovation. Its plant with powerful CNC machining centers is state of the art and produces the high quality for which the company has been known since 1879. The FAS brand presents its unique check valve. Thanks to its many types of connection – brazed, flare or flange – the check valve can be used in a variety of applications. The products are also very easy to maintain: if one of the check valves should show signs of wear after long-term use, the internal parts can easily be exchanged without the entire valve having to be replaced.

Quality is the main principle

AWA and FAS always place special importance on safety: experts check every single valve before delivery. AWA has also introduced comprehensive measuring and testing procedures. 100 percent of the products are tested in the company’s own helium tightness test systems to ensure that AWA products are gas-tight and pressure-resistant. This is one of many reasons why AWA has been certified for quality management according to ISO 9001. AWA’s environmental management system has also been certified according to ISO 14001 as a result of the company’s focus on sustainability.