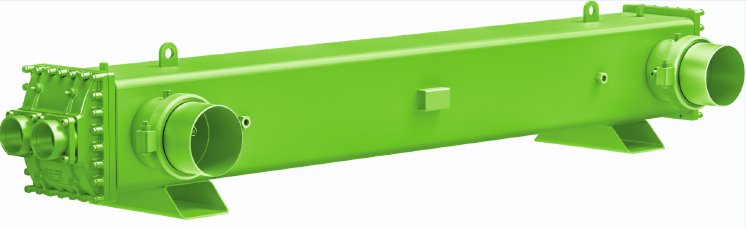

BITZER is squaring up to dry evaporation: Its unique square design combined with the exclusive patented refrigerant distributor makes the SQD series the most efficient dry-expansion evaporators available on the market. Furthermore, they are highly flexible with regards to both refrigerants and configuration. Operation is approved for all common refrigerants, as well as for low-GWP refrigerants such as HFC/HFO blends and HFOs.

The difference is in the details

The high efficiency levels of the SQD are guaranteed by bringing the dry-expansion evaporator to the upper limit of its performance possibilities while reducing the approach and maintaining the superheating at the same time. The result is a direct and remarkable impact on the cooling system’s efficiency at full and part load. The evaporator’s square design features an improved baffle window for optimised water flow. Furthermore, it has a larger heat transfer surface than evaporators with a traditional round shell design, resulting in higher efficiency.

Even refrigerant distribution

The SQD features a patented refrigerant distributor which allows for a consistent distribution of refrigerant through all pipes. The counterflow inside the evaporator optimises superheating and ensures the best possible efficiency. For every evaporator size, several distributor models are available.As compared with flooded evaporators, the BITZER SQD requires much less refrigerant charge – up to 70 per cent less than traditional flooded evaporators and up to 50 per cent less than hybrid evaporators. Its maximum evaporation temperatures are close to the working conditions of conventional flooded evaporators.

All-rounder for air conditioning and process

SQD evaporators can be configured with up to three independent refrigerant circuits and represent the optimal solution for air conditioning and process-cooling duties with capacities up to 2 MW, where high efficiency is a must. In air conditioning applications, they allow liquid chillers to reach Tier 2 efficiency targets, as indicated in the European EcoDesign Directive. In process cooling, they ensure reduced energy consumption performances under both full- and part-load conditions. They can also be used in marine and medium-temperature refrigeration applications.

The SQD achieves an operating pressure of up to 24.2 bar on the refrigerant side and 10 bar on the water side. Customers can choose between eight shell sizes from 150 to 500 mm and up to eight lengths. The water connection can be configured on both the left and right side; thermal insulation is optionally available.

As an independent specialist for refrigeration and air conditioning technology, BITZER is present all over the world: with products and services for refrigeration, air conditioning and process cooling as well as transport, BITZER ensures optimum temperature conditions for trade in goods, industry processes and indoor climate control – always considering highest possible energy efficiency and quality. BITZER is represented all over the world with 72 sites in 37 countries, including its sales companies and production facilities. Trade and service partners included, the BITZER network of manufacturing, development and sales extends to almost all countries in the world. In 2019, 3,800 employees generated a turnover of €808 million; expenditure for research and development totalled €46 million.

Overview of images

Images may only be used for editorial purposes. This usage is free of charge if ‘Photo: BITZER’ – and a free copy of the publication is sent to us. Images may not be modified or altered, except to crop out the background surrounding the main subject.