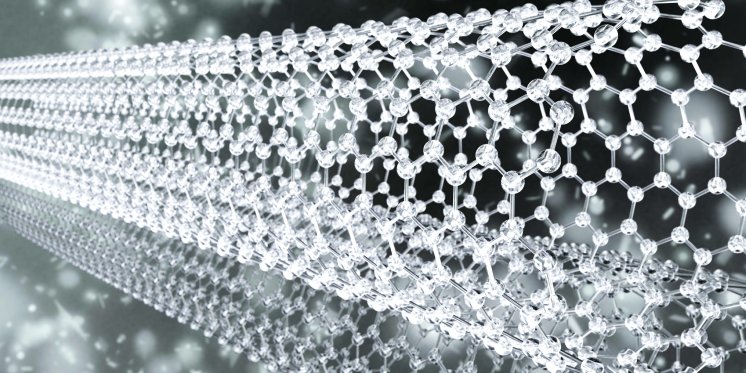

This year´s focus lays on the newly commercialized carbon nanotube dispersions, E35B+ and T50B, which contain a high loading of surface modified carbon nanotubes. These new dispersions from Bomar’s collaboration partner, Mechnano, provide an even and Isotropic distribution of discrete carbon nanotubes in a UV-curable resin, and can be used wherever electrical conductivity, or anti-static properties are required. Additionally, Bomar has launched BR-581MT, which guarantees a tack-free surface after curing, directly addressing the specific needs of UV nail gels with requirements for low heat generation during curing with good acetone removability.

The bio-based products BR-1041MB, BR-1042MB, BR-1043MB, and BR-1044MB offer significant bio-content and numerous technical advantages over petrochemical analogs. They exhibit significantly lower viscosities while maintaining comparable mechanical properties, enabling versatile applications for materials ranging from highly flexible to rigid. Moreover, these oligomers show relatively low color compared to other high bio-content materials and are therefore well suited for transparent and pigmented applications, especially for UV-curing nail gels in line with the latest cosmetic regulations regarding inhibitor concentration.

Visit our Bomar booth to also learn all about our dendritic thioether oligomers and their cure-boosting properties, as well as their excellent adhesion properties on a variety of substrates, including ABS, aluminum, glass, polycarbonate, PMMA, and stainless steel. Additionally, Bomar will demonstrate the ability to emulsify hydrophobic formulations into waterbased systems using the hydrophilic, trifunctional urethane acrylate XR-9416.

Our experts are ready at RadTech to discuss the oligomers and the tailored curing systems, and to facilitate their integration into your existing manufacturing processes.

For more information about our company and our products, visit: https://bomar-chem.com