In contrast to conventional methods such as chalk or colour markings, our marking system offers a sustainable solution. The marking carried out during production creates durable markings that virtually rule out mix-ups and illegible markings.

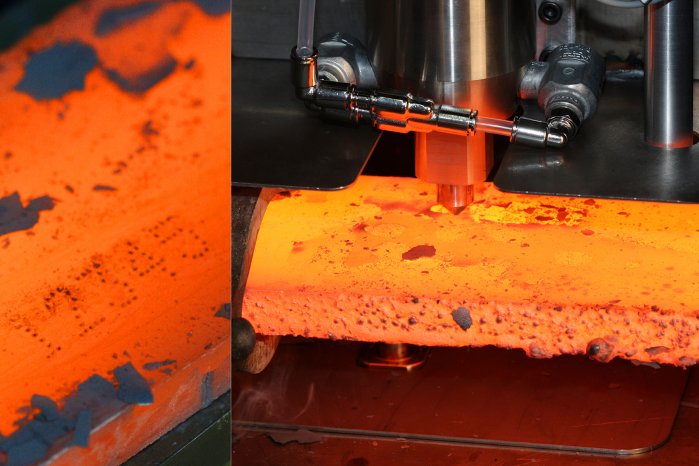

Our marking system uses a six-digit numeric code in dot matrix, which is placed directly on the hot metal sheets. With a character height of 15 mm and an imprint depth of at least 0.5 mm, we guarantee optimum legibility, even for character recognition systems. The marking remains clearly recognisable, even if scaling occurs. Automatic marking is carried out by three marking heads that receive the code from our intelligent control system. The upper marking head scans the surface and adapts to the sheet thickness, while the lateral marking head compensates for unevenness of up to 12 mm.

In this particular scenario, the system is pneumatically moved to the basement below the rolling mill between the marking processes to protect it from persistent heat. It is equipped with temperature sensors, an air cooling system and special protective mats.

Our flexible configuration also enables the seamless integration of the marking machine into various systems, making it a versatile solution for individual marking tasks.