Chris started making his first clock in 1981. "I originally wanted to make a traction engine, but didn't have a lathe," he explains. "Being newly married, we didn't really have the money to buy one, but on a trip around a model engineering exhibition, I saw a book on making a clock. If I had a lathe, dear, I could make you a clock . Problem solved, so I made my first clock. The traction engine came later, along with a part built railway engine." Chris has built around a dozen clocks - most have been commissioned by, and given as presents to, friends. He still owns four finished clocks, and is currently working on a Vienna Regulator.

Why is he so keen on making clocks? "I like the fact that clock making turns engineering on its head - for instance, the wheels are made from brass, which is soft, whereas the pallets (the little click-clack that releases the escape wheel when the pendulum swings) are glass hard steel, but they always wear first due to embedded dust in the brass acting as a lap. We think of clocks as precision work, but if you make them to too tight tolerances, they won't work - everything needs to be 'a rattling good fit . The early clocks were made of iron, probably by the village blacksmith - sat in a church tower, covered in pigeon droppings, and probably lubricated by tallow - hardly precision, but they worked, and continue to do so."

From Professional to Personal

Chris has been using MEDUSA in his professional life since 1984, and is the resident guru at CU Phosco Lighting, the UK s largest manufacturer of outdoor lighting products. "Today the Fourth Generation, MEDUSA4, runs on Windows XP Pro, and my company uses the latest colour raster module for positioning PDFs of customer site plans as backdrops for layouts and lighting designs, complete with illuminance calculations."

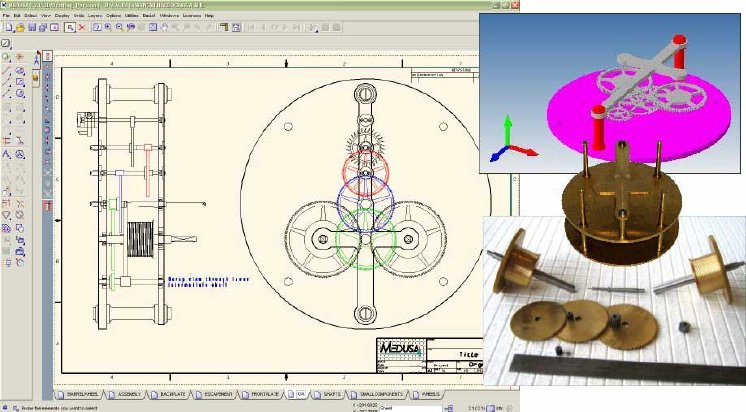

At home, Chris downloaded MEDUSA4 Personal to help him design and build his clocks, creating layout and detail drawings, and working out dimensions. He buys in standard parts, like springs, dials & ballraces, but makes the remainder. "Along with general layout and arrangement drawings of a clock, I create detail drawings of the various components, such as shafts with lengths to shoulders, or laying out the details of the escapement, the mechanism that regulates the clock."

After completing the design, he used to do a lot of the intricate work by hand. "My wife is very patient, but there s always lots to do around the house, so I rigged up my own CNC machine to speed things up a bit," he says, "Cutting the gear teeth is quick and easy. You can cut all the wheels for a clock in an afternoon, but marking out and cutting the rim, spokes and hub is something else. Even with CNC you have to clear up and polish the cut edges, but it helps." And so while Chris house might occasionally feel the neglect of the model engineer, his friends and family, along with the engineers at CAD Schroer, truly appreciate the fact that he continues to make the time for MEDUSA4 Personal and these remarkable clocks.

For more information and to download the FREE version of MEDUSA4, please visit www.cad-schroer.com