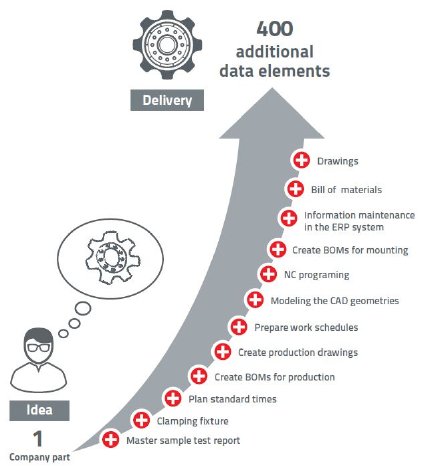

But why are these costs so high? A survey conducted by Rolls-Royce shows that every additional self-designed part in consequence requires 400 additional data elements, processes and parts. The expenses for every new component are accordingly high.

But also unnecessarily created standard & supplier parts cause significant costs. Because the procurement price is only the tip of the iceberg.

Looking at the entire life cycle of a product, the complete parts costs are much higher than the procurement price. Factors like purchase negotiations or administration costs are often disregarded.

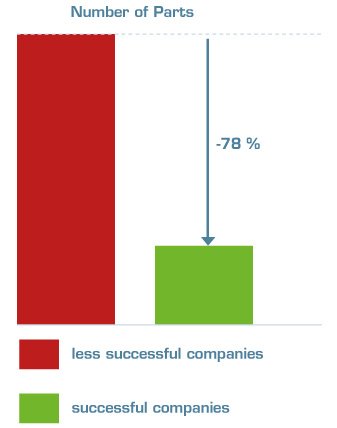

Successful companies have fewer parts

A study by K. Ehrlenspiel affirms that the respective market leaders have fewer parts in their industry. The Strategic Parts Management PARTsolutions by CADENAS supports companies during the development phase of products, firstly by increasing the reuse rate of parts and secondly by reducing the creation of new parts and therefore their parts inventory.

For effective reduction of parts cost, there are two solutions: First, the number of parts can be reduced and the parts reuse be increased. Secondly, own parts can be replaced by standard or purchased parts.

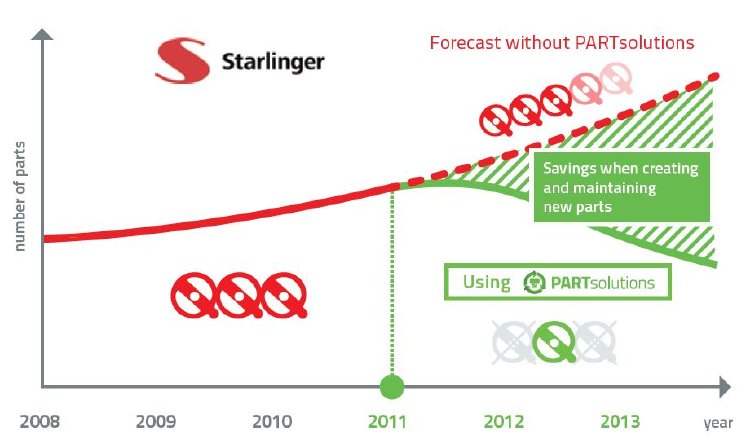

1 million Euro savings at Starlinger due the strategic parts management

Reducing newly created parts and increased parts reuse can be done successfully, the Austrian company Starlinger is a perfect example: The amount of new A- and Z-parts created was decreased by approximately 1,100 parts during the observation period due to PARTsolutions. With estimated processing costs of approximately 700 EUR for a newly created part and annual maintenance costs of approximately 100 EUR, the savings amount to about 1 million Euros.

For more Information about optimization of part costs in engineering have a look at our PARTsolutions brochure or at: www.cadenas.de/strategic-partsmanagement