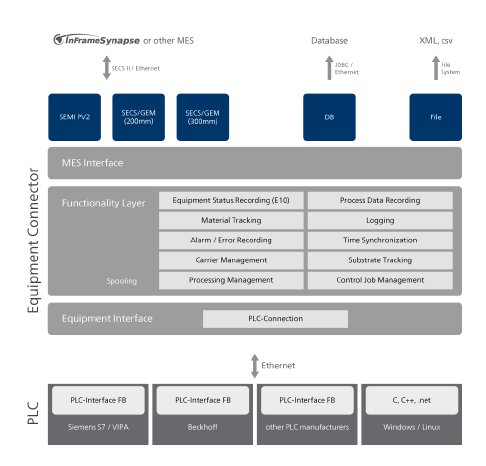

Usually, the subsequent connection to the plant is associated with time consuming programming. On the other hand, creating an IT interface with the help of EQC is done by configuration which reduces costs enormously, up to 75 percent. In combination with the low effort required for interface implementation and MES integration, this creates real added value. Thanks to the open interfaces, the EQC is flexible and can be linked to any MES, whether from camLine or another vendor, and can retrieve data from all commonly known machine controllers (PLCs).

camLine supports the implementation of these interfaces and the MES integration drawing on 30 years of experience and proven broad knowledge. As a member of the international semiconductor and photovoltaic association SEMI, camLine was also actively involved in the development of interface standards (SECS/GEM).

Besides the fact that the manufacturers benefit from the numerous advantages of the InFrame Synapse Equipment Connector, the equipment vendors (OEM) can make their equipment talk, i.e. implement standard-compliant or individual IT interfaces for their machines easily and without great effort. In the end, making IIoT connectivity available at low cost is a big plus.

For more details on the InFrame Synapse Equipment Connector (EQC):

https://www.camline.com/...