Innovative processes for perfect welding results

The focus of the 200 m² exhibition booth is on the wide range of welding processes for different materials and components. No matter if thick or thin, steel or aluminium, manual or automated – here you find the right welding process for every product requirement. At the EuroBLECH 2016 CLOOS will present the new Root Penetration Control (RPC) welding process for the first time. The controlled short arc process is particularly suitable for the special requirements of pipe constructions, for root welding or thin plate welding. The RPC process is characterised by a stable, low-spatter arc which is resistant to external influences by the welder. Due to the low heat input, the energy requirement and the component distortion reduce considerably. This brings the costs for possible reworking down to a minimum.

New Tandem Weld functions for efficient welding

Besides, CLOOS will present the new functions of the Tandem Weld process for automated welding. Since 1996 CLOOS has been the global market leader in Tandem welding and has continuously developed this process. A total of several thousand Tandem Weld applications by CLOOS are in use. New synergy characteristic curves allow higher deposition rates and thus higher welding speeds. Besides, the new robot functions facilitate programming. The robot uses the Wire Orientation Vector function to recognise the position of the welding torch and the welding direction automatically which also reduces the programming expenditure.

High-quality power sources for versatile applications

During live-demonstrations of manual welding trade visitors can experience the wide model range of the CLOOS welding power sources from entry to premium. The visitors can discover the new TIG GLW 502 welding machine and also the new QinTron Pulse for MIG/MAG welding with a pulsed arc.

Another highlight is the QINEO Pulse for manual and automated welding. The main advantages of the powerful multi-process system are particularly versatile application possibilities and perfect welding characteristics. The QINEO Pulse is available in three capacity classes and combines five different welding processes in one machine. The QINEO Champ high-tech welding power source meets the highest demands at complex requirements in automation.

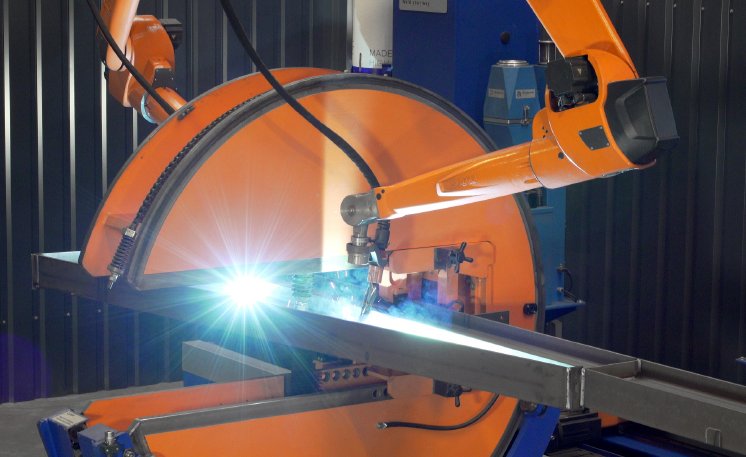

Individual automation solutions in all industries

With the QINEO welding machines, QIROX robots, positioners and special purpose machines CLOOS develops and manufactures customer-specific automated welding systems so that the users are able to meet the growing requirements of the automated welding technology. The portfolio comprises simple, compact systems as well as complex, chained systems with automated workpiece identification and loading and unloading processes.

CLOOS at EuroBLECH 2016:

Hall 13, booth E49