In the aviation and aerospace industries, the use of lightweight materials is an absolute must from an economical point of view. Therefore, fibre-reinforced plastics and composite materials, such as CFRP and GFRP, are being increasingly used in the aircraft construction industry. The fact that they are lightweight means that more energy-efficient aircraft can be built that reduce fuel costs and protect the environment on account of their lower drive power. At the same time, their extreme hardness and strong abrasive quality can push cutting tools to the max in processing them.

Manfred Weigand, Product Manager at CemeCon AG in Würselen: "With these materials, economical machining with a long service life can only be achieved with corresponding tool coating, optimally adapted to the cutting process and the material." As one of the leading manufacturers and developers of coating materials for milling cutters and drills, CemeCon AG also provides high-quality solutions for CFRP and GFRP machining. The patented diamond layers from the CCDia® series combine the excellent adhesive strength of crystalline coatings and the outstanding smoothness of nano-crystalline coatings by means of a special CVD process. They prove themselves to be particularly powerful in the precise cutting of abrasive materials.

CCDia®FiberSpeed optimises tool lives

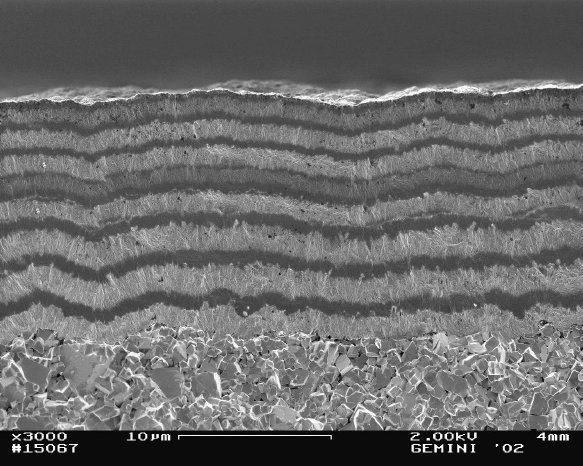

With CCDia®FiberSpeed's multilayer coatings, CemeCon offers a coating material specifically adapted for the machining of fibre-reinforced composite materials. No less than 14 layers of crystalline and nano-crystalline diamond structure considerably improve the cohesion of the individual diamond crystals inside the coating on tools for machining CFRP and GFRP, for example of a 10 mm solid carbide spiral drill. Therefore, compared to tools with AlTiN or AlCrN coatings, tool tool lives can be up to 8 times longer.

CCDia®FiberSpeed is also the first choice in terms of process safety. "With CFRP materials, the fibre is not cut during machining but actually broken", explains Manfred Weigand. "There is therefore a danger that it might come away from the much softer and thermally very sensitive resin matrix or, if the cut isn't clean, it can be left behind in the form of fibre protrusions. Each delaminated fibre, however, weakens the structure of the overall CFRP component. Our CCDia®FiberSpeed coatings counteract this with outstanding thermal conductivity properties and optimal layer tension ratios. The diamond multilayers also protect the tool and hence keep the edges sharp."