Highly accurate material processing

In many industries, very small-diameter cutting tools are employed. Since this depends on the most accurate processing and allows for only minimal tolerances, standard commercially available coatings are often too thick. Tailored to each tool and its intended use, CemeCon (www.cemecon.de) HPN1 now comes with a thickness of as little as 1.5 µm - guaranteeing one hundred percent accuracy during machining and a long service life for the tool.

HPN1 Plus - for applications requiring thicker coatings

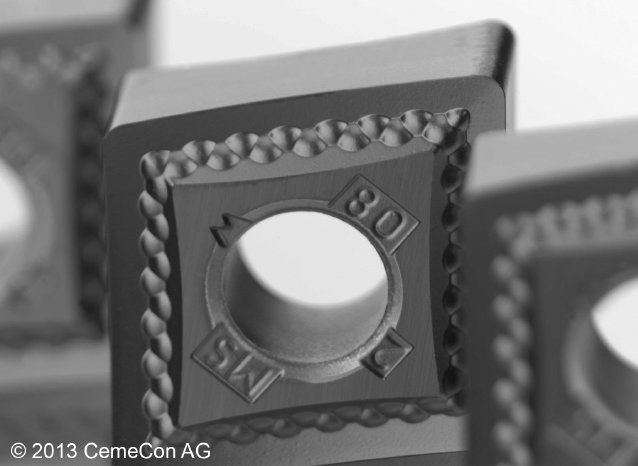

After very successfully coating cutting inserts with thicker PVD layers such as HYPERLOX Plus, coatings specialist CemeCon is now also providing thicker tool coatings with the new HiPIMS technology and offering HPN1 Plus at a thickness of 8 µm for cutting inserts.