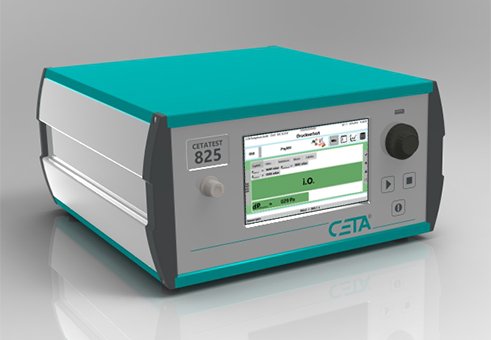

The device housing in 4 height units stands out by its innovative design. The integrated 7” touch screen with intuitive, clearly arranged user interface enables the display of a wide range of information (such as measurement curves, histograms). The device can be operated both from the touchscreen and from a dual jog dial. Separate start/stop keys ensure operational safety even in harsh industrial environment. An alternative model with offset control panel for integration in a test stand is currently in development.

Combining the advantages of a real-time microcontroller for measurement processing and industrial PC architecture offers various possibilities to increase the functionality of the device. For example, it allows flexible configuration of additional test phases. An event-driven test process can be achieved through the integration of external sensors (such as temperature sensors). User-oriented functionalities facilitate the setup of the device (for example conversion to other units of measurement).

The ring buffer can store over 1 million measurements. A total of 256 test programs are available.

The pneumatic system has been flow-optimised and the inherent volume of the measuring circuit significantly reduced. Integrated security functions are provided for the detection of internal system errors. This ensures a high degree of production reliability.

Various bidirectional wireless connections (Bluetooth, wireless LAN, NFC) are provided in addition to the usual industrial interfaces. A special app for tablets and smartphones is to be launched in the near future. The x25 series is fully interface-compatible with the x15 series. The established application software „CETA Soft 2G“ can also be used with the new devices. The x25-series is all set to meet Industry 4.0 demands.

As in the previous series, all leak testers of the CETATEST x25 series will be delivered with DAkkS calibration certificate (in accordance with the standard DIN EN ISO/IEC 17025) and 3-year warranty.

CETATEST 825 will be available in the 4th quarter of 2019. Further models (volume flow and mass flow measurement) and multichannel devices will follow in the near term.

CETA will be present at the CONTROL 2019 in Stuttgart from 07.th - 10.th May 2019

in hall 7, stand 7207.