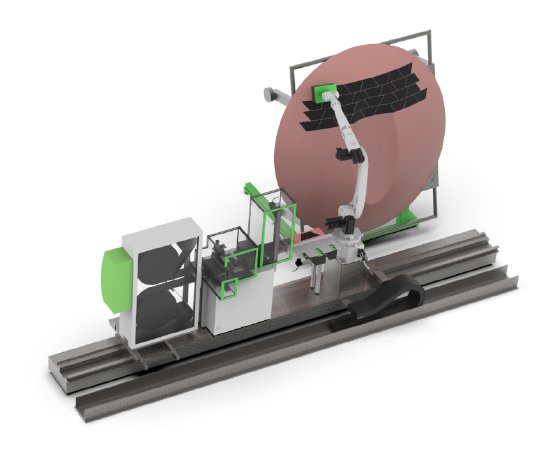

Equipped with numerous sensors monitoring all relevant process parameters, Fiber Patch Placement production systems of Cevotec’s SAMBA Series allow for a continuous quality control and monitoring during the production process. “Particularly in the aerospace industry, an industry that does not forgive mistakes in manufacturing, the composite parts produced in today’s semi-automated production are subject to individual unit tests to ensure specification compliance and therefore a maximum degree of flight safety,” reports Felix Michl, CTO at Cevotec. Working with Fiber Patch Placement, sensors of the production system monitor key parameters of the production process: from cutting the patches from a tape spool to pressure-controlled fiber deposition. In particular, a special vision system checks each individual patch for quality and dimensional accuracy before further processing in order to guarantee that 100% of the input material is according to specifications. This reduces the required effort for the final inspection enormously and lowers the non-pass rate of produced parts.

Production data are analyzed and compared with a database of previously processed patches. Deviations can be promptly detected, and the system takes appropriate corrective measures fully automated. “Incorporating machine learning concepts, the algorithms become more intelligent with each patch processed in the database,” Michl continues. On the basis of this data, process tolerance specifications can be minimized, which in turn guarantees a consistently high placement quality. The time and cost required for single unit tests are significantly reduced.

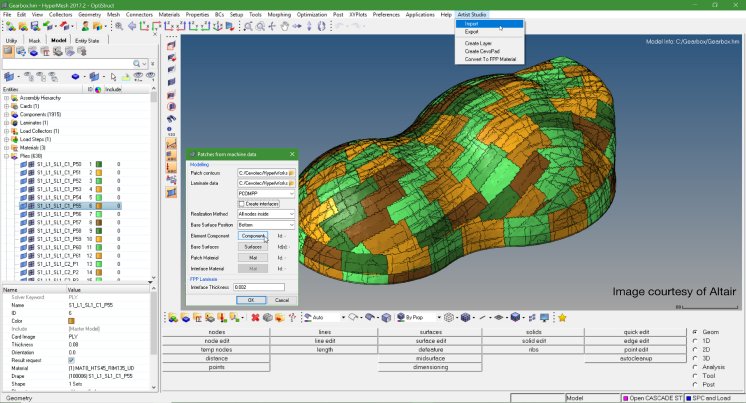

Additional potential to accelerate production and especially development processes offers Cevotec’s latest software extension: A plug-in for the modeling software HyperMesh, one of the leading FEA preprocessors. “Based on the data defined in PATCH ARTIST regarding geometry, position and alignment of the patches, the ARTIST STUDIO plug-in automatically generates a detailed image of the patch laminate in HyperMesh,” explains Cevotec’s EVP Dr. Neven Majic. The contour of each individual patch is used to model fiber orientations and overlap areas. Ply-based shell models as well as solid and cohesive zone models can be used for analysis, which can be performed on both sublayer and patch level.

At Advanced Engineering Show in Birmingham (booth N86) and Composite Europe in Stuttgart (hall 9, booth E60e) Cevotec presents the sensor-enhanced systems and the ARTIST STUDIO plug-in. In addition, as already announced, the SAMBA Multi production system for automated multi-material layout of aerospace-specific sandwich components, and the TAPE ARTIST software module for combined FPP and AFP laminate planning will also be presented. All new Fiber Patch Placement features are available towards the end of the year.