Hofmann Leiterplatten GmbH specialises in manufacturing PCBs with up to 8 layers, either as a prototype or in small quantities. Especially customers from R&D departments appreciate the company’s express service that is able to provide the first sample within 24 hours from submitting the CAD files. Hofmann Leiterplatten GmbH provides all standard PCB types, manufacturing processes as well as surface engineering. Long-term expertise in manufacturing PCBs in IMS-technology (ISM: isolated metal substrate), also known as metal core PCBs, make Hofmann one of the leading suppliers of IMS-PCBs in Europe. A close cooperation with the supplier Bergquist and a high availability of materials from stock recommend the medium-sized company as a dependable, just-in-time partner.

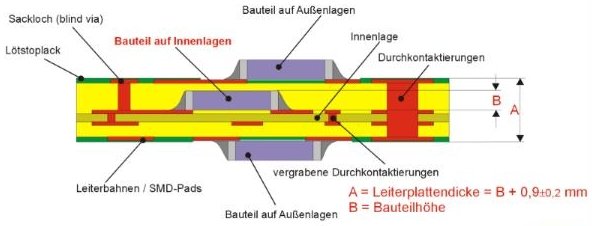

The AML-technology, developed by Hofmann, is a patented process for embedding components with altitudes in the range from 300 µm to approx. 3 mm directly into the PCB. Thanks to the internal assembly layers, the PCB gets more compact and is able to carry more components at a given size. The embedded components are hermetically sealed against environmental influences like moisture, dust, vibration, impact and interference. In addition, an AML can also work as a case and thus make the housing obsolete. Despite the bouquet of advantages, AMLs are reasonably priced, as they can be manufactured by applying standard processes.

The components are entirely embedded in epoxy resin, therefore the heat is dissipated evenly throughout the module; hot-spots at specific components are considerably reduced. The thermal conductivity of AML is in the area of 0.3 W/mK – compared to only 0.03 W/mK of air. Therefore, embedded components are capable of carrying a significantly higher thermal load compared to conventional designs.

Manufacturing of front panels

Hofmann Leiterplatten GmbH also manufactures front panels and mechanical parts for the electronic industry. These parts are either manufactured in-house from aluminium or plastic according to the customer’s CAD drawings by state-of-the-art CNC machines, or Hofmann finishes parts provided by customers by milling, engraving, applying threads or counter-bores. Customers providing comprehensive CAD files can save a significant amount of money as this eases the development of CNC-programs.