In addition to such important components as the gas generator (explosive charge), the collision sensor and the airbag itself, safe electrical connection of all components are part of the security concept. After all, the information from the collision sensor must reach the primer of the airbag in the steering wheel .

In the average 15-year life of a vehicle, the steering wheel is turned millions of times in both directions. Therefore, one had to consider a whole new connection type, how to reliably transfer electrical ignition voltage.

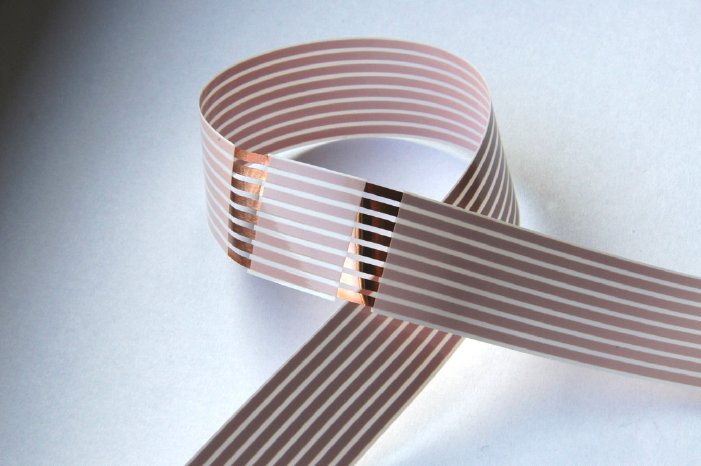

The result is a coil, wound like a clock spring. And similar to the clock spring, the line is composed of a very flat but flexible construction.

It was found that a mix of polyester foil and a heat-activated adhesive turned out ideal. The relatively stiff, but chemical- and age-resistant foil generates a flexible bond with the strong adhesive. Two external layers of foil protect the in-between laminated cables reliably from damage and corrosion.

So this so-called laminate cable (FLC, flat laminated cable or FFC, flat flexible cable) combines the rigid part of the steering column with the rotating part of the steering wheel throughout a car's life. So that the airbag can be released reliably at any age of the vehicle.

CMC Klebetechnik delivers components for this system since the introduction of airbags into mass production in the late 1980s.

In doing so, 20 million square metres of produced laminate foil came together by now. This means about 660 million metres of laminated cable. An impressive number, if you consider the amount of cars this corresponds to. As a consequence a very high percentage of all vehicles produced in Europe drives around with laminate cables manufactured with laminated foils by CMC Klebetechnik.

For more information, see http://www.cmc.de