In some cases the insulation thickness must be higher than the common standard thicknesses of 25µm or 50µm due to structural or electrical reasons. The current standard process is to laminate two or three insulation film layers together. The application behaviour, however, is often limited through the adhesive used.

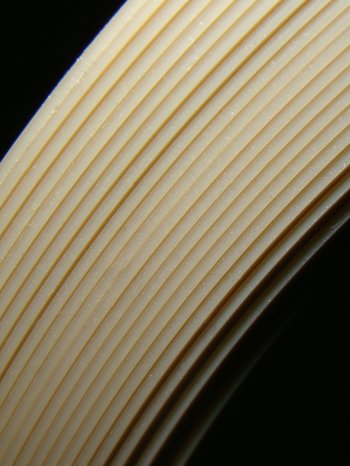

As a preferred Victrex partner, CMC Klebetechnik now offers an alternative to the partly expensive multiple laminates: the thermoplastic APTIV™ high performance film. This is a very pure, semi-crystalline film based on VICTREX® PEEK™, available in thicknesses of 8µm to 750µm. The standard width for this film is 610 mm.

APTIV™ film has an excellent electrical thermal resistance (UL RTI rating of 200°C (392°F)) and good electrical insulation values. The electric strength of the film is 120 kV/mm at a thickness of 125µm and 40 kV/mm at a thickness of 500µm. The material displays extremely high abrasion resistance as well as excellent hydrolysis, chemical and radiation resistance.

This film material is superior to other materials such as FR4 because it can be die-cut to customer-specific requirements. Unlike ceramic insulators or injection-molded parts for example, these films feature excellent bending characteristics, enabling easier assembly. For the already available APTIV™-based tapes, CMC Klebetechnik uses a polysiloxane adhesive with a resistance of up to 350°C, ensuring good adhesion and thus quick assembly on virtually all surfaces.

Engineers who must provide, in the context of product development, reliable electrical insulation for components with high temperature development (i.e. quartz lamps for laser pumping) and requiring material thicknesses from 0.2mm up to 0.75mm can now test APTIV™-based films, die cutting parts and tapes of CMC Klebetechnik for their applications.