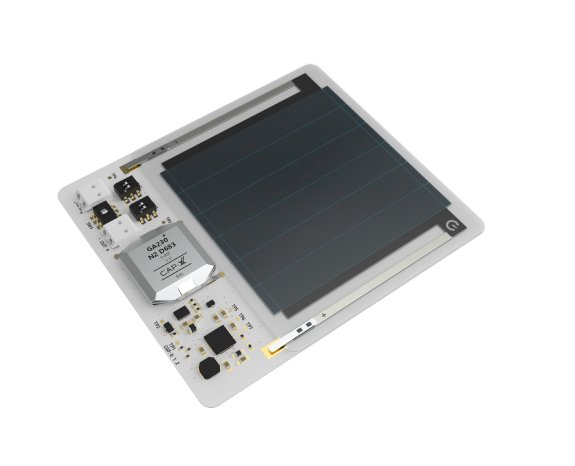

The light cells for indoor use are optimized in such a way that they generate enough power from the ambient light of LEDs or fluorescent tubes to fully or partially secure the power supply for wireless indoor applications with low power consumption, such as IoT devices or various sensors. Even the smallest amount of light is "harvested" and stored in the integrated energy storage device in order to guarantee the uninterrupted operation of the devices even in complete darkness for several days. An aspect that is of interest to end customers is the omission of maintenance costs for battery replacement and the reduced use of single-use batteries has a significantly lower impact on the environment and finite resources. In addition, the light cells from Epishine are non-toxic, based on organic electronics and are encapsulated in recyclable plastic. The scalability of the cells, which is important for development engineers, is given by the fact that the entire manufacturing process is based on various techniques of flexibly printed electronics (roll-to-roll | R2R process) and the thin, light design with a thickness of only 0.2 mm can easily be integrated into typical Electronics housings based on plastic.

One of the most recent pilot projects in which the light cells are being used successfully are food refrigerated counters in which the cells work reliably in temperatures below zero of up to -20 °C and generate electricity from the counter's own lighting. Since commercially available batteries quickly reach their performance limit by losing up to 50% of their capacity at sub-zero temperatures, this application shows, among other things, one of the versatile technical and economic uses of these light cells. Epishine LEHs are flexible and can be used alone or in tandem with capacitors to replace batteries or extend their life in low power applications.

With this new product access, CCAG shows its customers once again that it has understood their innovative strength and, as a full-range supplier, it can help to advance the development of new products until they are quickly and competitively marketed. CCAG offers interested customers access to various reference designs from companies such as e-peas, Miromico or SiLabs, and Epishine has a compact lux logger available for feasibility studies that determines whether the light output at the place of use is sufficient for the planned application.

You can find detailed information and downloads on the "energy harvesting light cells" here in the CCAG webshop:

This press release on the Computer Controls AG website

https://www.ccontrols.ch/ch_en/news/

CControls – Social Media:

YouTube

About epishine

Epishine's business is based on pioneering manufacturing breakthroughs within printed organic solar cells. Their disruptive process steps provide a unique scalability in terms of manufacturing and also industry leading efficiency in low light. Epishine's first product is optimized for low energy lighting indoors. It’s a small, thin, and flexible light cell, printed on recyclable plastic that is easily integrated into small electronics where it converts the ambient light into electricity. The light cells eliminate the need for costly battery replacements in wireless sensors and similar devices in our increasingly connected world. The company was founded in 2016 and has 25 employees with headquarters, lab and manufacturing in Linköping, Sweden. www.epishine.com