- ContiTech presents sustainable products for machinery and plant engineering

- Energy supply and agricultural machinery, two key issues for Russia, the trade show's partner country

- Electrically powered two-wheelers a promising future market

- WeP Partner Concept celebrates 10th anniversary

Under the 'We care!' slogan, ContiTech AG is showcasing its comprehensive technological and developmental expertise in the manufacture of sustainable products for machine and plant engineering at the Hannover Messe (April 8 - 12). The technology company's approx. 500-square-meter booth (F18 in hall 6) provides an overview of what's new in rubber and plastic, the materials of the future. This year, ContiTech has boosted its presence at the Messe with a booth (B23 in hall 25) devoted to drivetrain technology at the leading trade fair "Motion, Drive & Automation". On display there are drive solutions for mechanical engineering applications and two-wheelers as well as vibration isolation components and hose lines.

"Our presence at the Messe and our principle of 'Engineering Green Value' underscore the claim we make of contributing to the general well-being of society," affirms Heinz-Gerhard Wente, CEO of ContiTech AG. "With our expertise, our high level of flexibility, and our quality standards, we intend to up the quality of human life." Under the 'We care!' slogan ContiTech is showing how its systems help safeguard supplies for people worldwide: in the food and beverage industry, in the provision of clean water, in the operation of irrigation systems, and, above all, in agricultural machinery and in the reliable extraction and transfer of raw materials. ContiTech's 'We care!' slogan also points to the company's reliance on eco-friendly technology. Examples of this are hoses for the purification of tractor exhaust gases, ultra efficient drive belts for harvesters, or a specific technology for straw balers.

Driving the future: On the road and in the machine-building industry

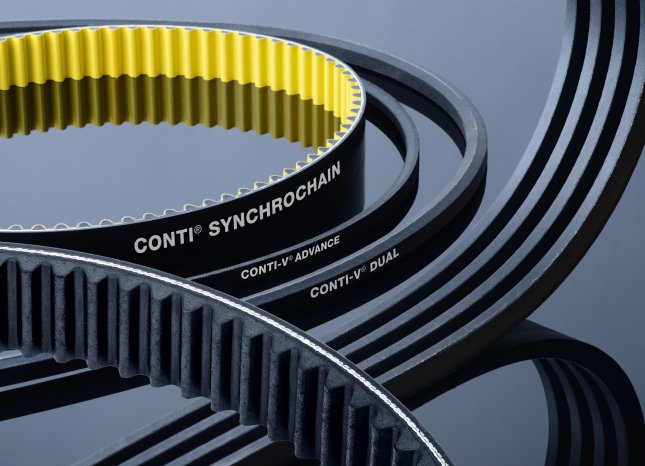

The ContiTech Power Transmission Group's presentation at the Hannover Messe focuses on heavy-duty belts for applications in machinery and plant engineering, in two-wheelers and in new eco-friendly drive belts. On view for the first time is a new high-performance polyurethane timing belt with carbon cord as tensile member. Its ultra reliable force transmission capability is paired up with high resistance to wear and abrasion. ContiTech has expanded its range of eco-friendly drive belts marketed under the BlueConcept label. The label stands for environmentally compatible and healthful industrial applications. In the future, a multiple V-ribbed belt will also be available.

The showing is complimented by drive belts for two-wheelers - the full gamut, from motorcycles and scooters through to bicycles equipped with electric motors. Going forward, the topic of individual mobility in metropolitan areas will continue to grow in importance and with it the demand for electrically powered two-wheelers. The ContiTech Power Transmission Group has developed a drive system for this purpose that replaces the classical chain with a drive belt - with a host of advantage for consumers. The drive belts and matching pulleys are developed in close collaboration with manufacturers and sales partners in the two-wheeler industry. "We are growing worldwide, not only with our high-tech belts for machinery and plant engineering but in the two-wheeler market as well," notes Konrad Müller, head of the Power Transmission Group business unit. "Our wide-ranging competence in the area of drive belts makes us a coveted partner."

Also available for viewing at the ContiTech booth in hall 25 are hoses for compressors and large hoses for use at construction sites as well as air suspension systems and ContiTech SCHWINGMETALL rubber-to-metal-bonded components for reducing vibrations in industrial vehicles and machines.

Russia - partner country at this year's Messe

Russia, this year's partner country, will also play a role at the ContiTech booth. ContiTech serves the Russian market from its sales office in Moscow. Technology from ContiTech Air Spring Systems will, for example, keep things moving at the 2014 Winter Olympic Games. Deployed in buses, express trains, and ropeways, too, products from ContiTech will transport a world audience to and around the event. For decades now, ContiTech Fluid Technology's Dunlop Oil & Marine segment has been a well-known name in the Eastern European energy industry thanks to its high-performance hoses for the oil and gas industry. ContiTech is, moreover, currently constructing a new plant in Kaluga, Russia, 170 km southeast of Moscow. Slated to go into operation in December 2013, the new plant will manufacture automotive air-conditioning and power-steering lines.

ContiTech makes added value tangible

For the tenth time, select ContiTech supplier partners will present their products at the trade show booth. Together with ContiTech, these value-added partners demonstrate how very important the interplay among all industry partners is in creating a high-quality product. Technologies range from special elastomers through to communications technology.