Electrically conductive fuel lines have been used for quite some time as OE equipment in the automotive sector. Now this application – not least because of appropriate regulations in the US – is becoming increasingly attractive for industrial trucks. The conductive inner lining made of FPM (fluorocarbon rubber) prevents static buildup at high throughflow rates which, in the worst-case scenario, could result in sparking and spontaneous ignition of the vehicle.

ContiTech’s highly flexible fuel lines are suitable for gasoline, diesel and biodiesel and can withstand operating temperatures from -40 to +150°C. The outer lining is resistant to radiant heat up to 150°C, and briefly even 175°C.

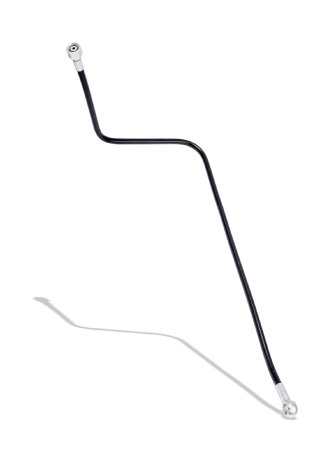

ContiTech’s oil lines, which are equally flexible and dimensionally stable, have been approved up to an operating pressure of 80 bar and are already successfully in operation in forklifts. They are suitable both as low-pressure hydraulic lines and for numerous other applications in which oil is transported. They consist of a PA pipe with a strength member. Although preformed, they are significantly more flexible than the PA pipes used up till now. This enables them to damp system vibrations which could cause cracks in the material and noise nuisance. They are also more flexible during fitting.