Presented next to many other advanced Mass Customization solutions at CoreTigo’s booth, Zimmer Group and CoreTigo’s joint demonstrator will feature the latest advancements in intelligent gripper solutions. This entails the integration of CoreTigo’s TigoHub i4 multiport hub which seamlessly converts IO-Link and digital IO devices into IO-Link Wireless with Zimmer’s grippers. Utilizing CoreTigo’s advanced industrial wireless communication technology, Zimmer gains the most flexible and simplest real-time connectivity between multiple IO-Link and digital grippers/sensors from the robots/cobots to the PLC. This allows Zimmer to offer its customers enhanced manufacturing abilities which can rarely be found on the market.

Flexible Solutions for Robots/Cobots and Other Factory Automation Solutions

Previously, communication with the robotic end effectors required external cabling, cable mounting accessories, and a wired controller. Such cabling is costly, maintenance-intensive, and time-consuming. In addition, cables limit the mobility and flexibility of the robot arm, increasing the weight of the arm and thus reducing gripping accuracy and speed. Tool and end effector exchange on the robotic solutions also require a modular, simple and flexible approach in order to optimize machine operation and workflow. A key component that has been missing in robotics so far is a wireless, highly reliable communication solution designed for factory automation.

Conventional wireless solutions, such as Wi-Fi or Bluetooth, are not suitable for real-time control tasks due to the high requirements of deterministic low latency, to support hundreds of sensors and actuators.

To meet these requirements, IO-Link Wireless was developed and specifically designed as a standard for high-performance wireless communication in factory automation. IO-Link Wireless enables the seamless and vendor-agnostic connection of the field level sensor/actuator with the PLC.

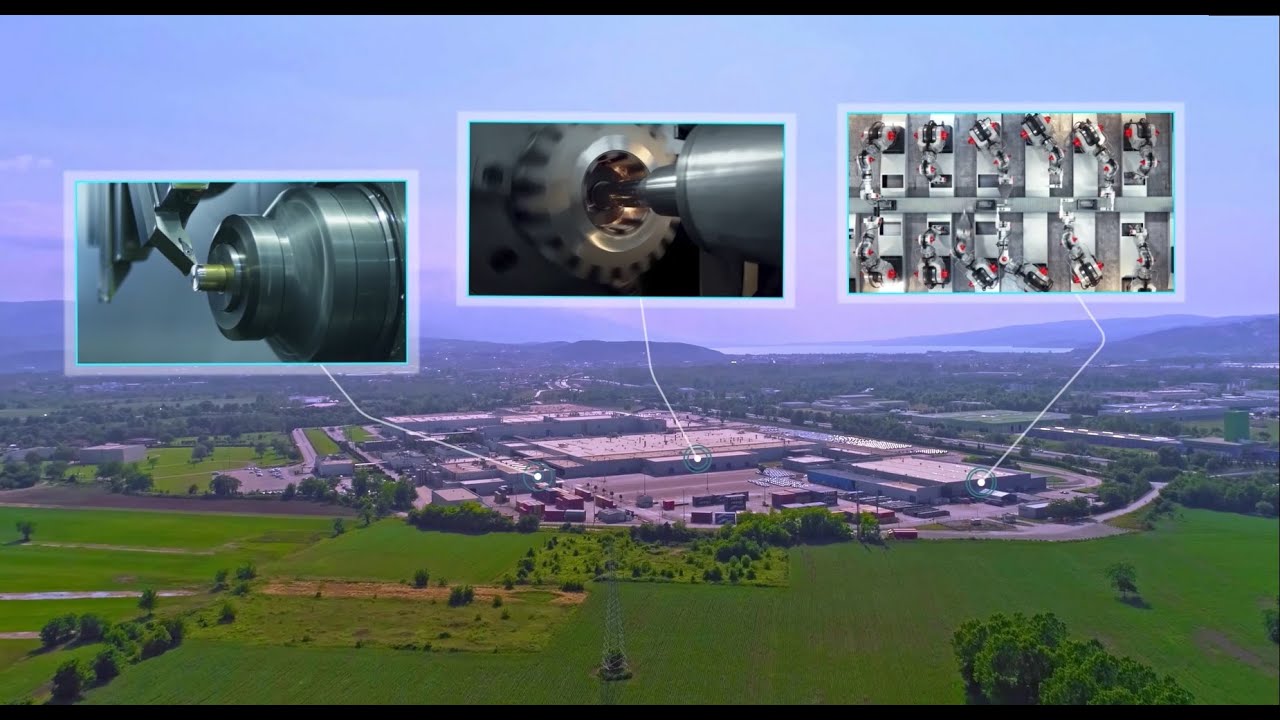

The advantages and value of this joint solution from Zimmer Group and CoreTigo can be gained not only for Robots and Cobots, but also for additional rotating and high-speed motion applications, where gripping and clamping equipment benefits from enhanced flexibility, modularity, and simplicity. Such applications include independent movers on transport track systems where actuators can be controlled while in constant motion, rotary tables where cabling through the slip rings is complex and costly, and carousels typically used in packaging machines that require multiple sensors/actuators per head.

These features and benefits are the enablers of fully flexible mass-customization operations and machinery. The highlight of which is the elimination of the tradeoff between customized production and agility, as now it is possible to gain both flexibility and speed.

German Innovation Award Winner

Forward-looking: As early as 2020, the Zimmer Group was awarded the German Innovation Award in the category "Excellence in Business to Business to Business". The title was awarded for the innovative gripper solution, illustrating the combination of Zimmer’s IO-Link grippers with CoreTigo’s IO-Link Wireless technology. Simultaneously, this system solution underlines the innovative strength with which both companies are shaping the path to fully-connected production. The course for the successful cooperation between the two companies was thus set, and further joint developments are planned.

Universal and Modular as Well as Wirelessly Networked

Robots play an important role in the manufacturing process of a product and must therefore be equipped with technologies that benefit both machine builders and plant operators.

Wireless technology is rapidly becoming a key technology that closes the connectivity gaps in factory automation and flexible communication in the machine. Secure, highly available, deterministic, standardized, interoperable and fast communication contributes significantly to the flexibility and modularity of a machine.

The value of wireless communication is evident in numerous stages of machine design, machine production, machine construction and the operator of the production facilities. For production companies, IO-Link Wireless technology offers numerous advantages and opportunities. The availability and productivity of a machine can be increased by minimizing changeover, downtime, repair times and increasing optimized processes.

For machine builders and integrators, the system solution from Zimmer and CoreTigo offers the possibility of quick, precise and safe conversion of IO-Link and digital grippers and other end effectors into IO-Link Wireless components and integrating them into the mechanical engineering concept.

The IO-Link Wireless Ecosystem Collaboration

At SPS Italy and Hannover Messe CoreTigo will present various IO-Link Wireless based Mass Customization applications live with its partners. Zimmer Group is an integral part of the continuously growing IO-Link Wireless ecosystem, alongside companies such as B&R, Laumas, VAHLE, Röhm, Rockwell, Schneider and many other companies. The interoperability characteristics of the global, worldwide standard are firmly anchored in the DNA of IO-Link Wireless.

To visit CoreTigo in person at SPS Italy 2022 or Hannover Messe 2022, schedule your meeting with CoreTigo executives and get a free ticket, click here: https://www.coretigo.com/2022events/

Zimmer Group will present the intelligent gripper solutions with IO-Link Wireless at Automatica with its experts on site.

For more information about CoreTigo: https://www.coretigo.com

For more information about Zimmer Group: www.zimmer-group.com

About Zimmer Group

With over 1200 employees, the Zimmer Group is one of the world's leading manufacturers of automation, machine and furniture damping components as well as process engineering. In addition, the Zimmer Group is an important and valued partner for system solutions for numerous well-known national and international companies in the fields of mechanical and plant engineering as well as the aviation, automotive and furniture industries. Since 1980 the Zimmer Group stands for high innovative strength "Made in Germany" and makes a sustainable contribution to the growth of its customers with technologically leading products and a sales network in 125 countries.