The operation of magnetic coupled pumps calls for the highest safety standards, particularly ensuring that off-design operating conditions causing breaches of the primary containment shell do not place the operators and immediate environment at risk. For some applications, extra measures that prevent the fluid from being released upon a failure of the primary containment shell need to be in place. In case of a leakage through the primary containment shell, a secondary containment allows for additional time to intervene for the operator and bring the pumping system to a safe state.

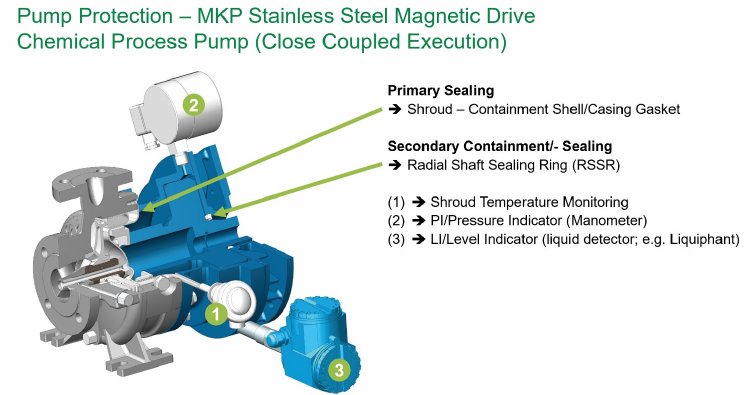

Magnetic drive pumps, manufactured by CP Pumpen AG (CP), have a primary containment shell which has proven itself robust in the field over the years and which is available in different materials and with different features depending on the application. The containment shell can be monitored using a patented shroud temperature monitoring system that indicates unwanted operating conditions effectively and quickly. In many applications this safety option is sufficient. However, certain applications require additional measures to prevent that the pumped fluid is released upon a failure of the primary containment shell. CP designed and qualified a secondary containment system consisting of a radial shaft seal ring (RSSR) which uses a pressure and/or leakage detector for monitoring. It is suitable to withhold pressures up to 16 bar with a rotating shaft up to 3600 rpm and for temperatures ranging from -80°C up to 250°C. Depending on the application, maintenance free operation for multiple years is anticipated.

The secondary barrier option is available for both, close-coupled or frame-mounted design. It provides an additional safety feature and makes the magnetic drive pumps suitable for safety critical applications with additional requirements for a secondary containment.

Author: Johannes Barth, Designer and Development Engineer, CP Pumpen AG

Visit us at ACHEMA2022, Hall 8, Booth F28 and experience our live demo!

Hashtags: #CPpumps #CPpumpen