The potential benefits of foreseeing the future are pretty obvious. It means you can prepare. Yet what you need to do to prepare for that foreseen future may not be quite so obvious. That is to say, you might need discernment to see subtle differences in approaches that will and won’t be suitable.

Industry 4.0 is a vision of the future that is foreseen. There is broad agreement on some of the major characteristics of the industrial future. Whether it’s called Industry 4.0, Smart Manufacturing, Digital Manufacturing and Design, Future Supply Chains or something else, it clearly will be more automated and more agile.

The underlying technologies have been in the news for years. They include mobile, cloud, social, big data analytics, 3D printing, and industrial internet of things (IIoT). Future possibilities have been emerging for a while, and fortunately the reality of using all of these fully is still out in the future. In this way, the future is somewhat obvious.

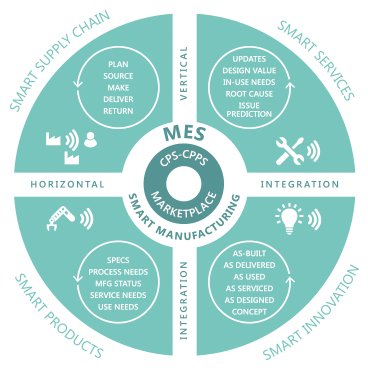

What’s not so obvious is what your IT and applications infrastructure must do to support the sea change of this foreseeable future. Of course, every software company wants to point to what it does as a foundational element for the future. I’ve already said I think modern MES/MOM has a critical role.

What’s important is to look past the basic category of MES and even the module functionality, to see the characteristics that the future demands. These are more subtle differences. For example, does the MES have:

- adequate data handling and analytics to manage larger volumes and higher variety of data from IIoT-enabled products and systems?

- workflows adequate to manage the new, more automated business processes?

- the ability to manage products, materials, and production centers in a decentralized fashion?

- integration and data context capabilities to support not only manufacturing but also smart products, supply chains, services and innovation?

Of course not everything is clear yet. Given that there are not yet standards for integration and the platforms are still being envisioned, it’s not possible to know everything you will need for Industry 4.0 to work well.

Fortunately, there are many elements already known and clear. Since it’s obvious that production is moving toward the Industry 4.0 vision, it’s worth starting to review the subtleties of your systems for their likely fit with that future.

What are you doing to embrace change for this future? I’d love to know your thoughts and preparations.

SEE ALSO: White Paper - Manufacturing Software for Industry 4.0. Embracing Change and Decentralization for Success by Iyno Advisors and Critical Manufacturing. Click here to Download.