Today we will try to establish the preferred path manufacturers should take towards transforming their operations from status quo, to the desired status, based on a scientific approach, which inculcates lean philosophy, GAMP (Good Automated Manufacturing Practices), MOM standards, ISA methods and focus on continuous improvement.

As a reminder - the strategy itself consists of three parts:

1) Manufacturing Maturity Model,

2) ROI justification for each project set,

3) risk mitigation assessment.

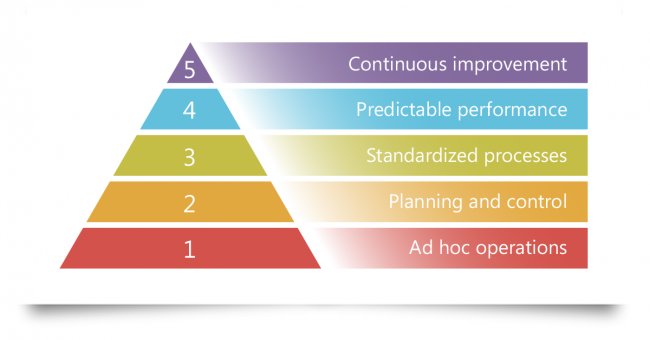

Now, there are five stages in the Manufacturing Maturity Model:

Level 1. Ad hoc operations, which basically signify manual processes for data collection, paper based reporting, less than fully automated plant and production processes across the organization in multiple plants, where the level of interaction between plant, corporate IT and management decision making is at a minimum.

Level 2. Planning and control. Here the plants may have individual IT applications which might exist in separate silos; there is some level of automation in plant operations but the overall connectivity across the organization is still poor, with plant and business being driven by IT applications which are not integrated.

Level 3. Standardized processes. The production and business processes across the group and amongst various plants are standardized, which leads to a leaner operation. In this stage applications like the MES, ERP and SCM which constitute the MOM for the organization are in place and allow standard processes to be formed and practiced across the organization.

Level 4. Predictable performance, with the application of lean and six sigma. The plants in the organization are now highly data oriented, where the management and process owners can easily predict the throughput and the performance across the plants and locations is synchronized with integration and visibility resulting from integration of IT applications within the MOM.

Level 5. Continuous improvement. At this stage the overall operation is demand/event driven, where IT is perfectly synchronized with the people, processes and structure of the organization and the performance of the operation is geared up for improving continually through collaboration of all business domains.

The MTS advocates every organization to perform a Manufacturing Transformation Assessment (or an MTA), which allows the company to gauge the level of maturity at which the current operation is. Generally standard checklists are used to determine the current maturity level, which in turn helps establish a baseline for the implementation of the MTS.

For more information about Mature Manufacturing - How Mature Is Your Operation Really? click here to read the complete blog post http://goo.gl/QoQVPw