( Francisco Almada Lobo, CEO, of Critical Manufacturing)

Manufacturers in high tech areas of production, such as semiconductor, were early adopters of MES technology. The concept bought a great deal of benefit to their sophisticated manufacturing processes. As time has moved on, these systems have been adapted to changing needs with upgrades and add-ons that were often proprietary.

This has left some production plants with a creaking MES based on hardware and software that is at the end of its life. The system, however, is such an intricate part of the plant that the thought of replacing it is a very scary option with risk, time and overhead costs that may be perceived as unacceptable. But nothing lasts forever and not upgrading the system may bring real peril to the future of the business.

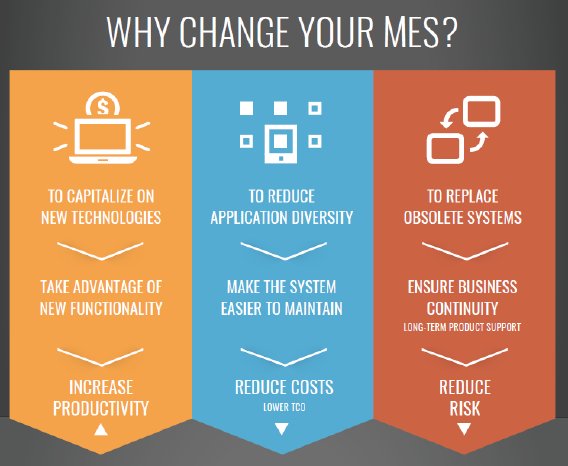

An old MES solution may limit the ability of a company to be competitive today and into the future. Increasing overheads for maintenance will be accompanied by a growing inability to adopt new technology choices that can increase productivity, reduce costs and improve quality. With changing market trends towards the demand for smaller batches of higher mix products with more customised, individualised solutions; getting left behind could be a very costly mistake.

In the semiconductor industry the majority of systems have been in place for over 10 years with some even dating back more than 20 years. Legacy MES constrain evolution and limit effectiveness with the main areas of concern being realistic modelling of the processes, comprehensive rule enforcement, functional coverage, integration and usability. These limitations can compromise traceability, precise control of processes, product quality and productivity.

Old MES also inhibit producers from capturing the benefits of major technological advancements in recent years. These include mobile computing; 3D and augmented realities; advanced statistical process control models; advanced data analysis software with the ability to even predict production scenarios, and the use of ‘Big Data’ to gain greater understanding of processes, costs and issues. These technologies are driving production efficiency to new levels; increasing the speed with which new products can be introduced and fostering greater innovation.

For sure, production can be so dependent on an old MES that the thought of turning it off will give most production managers sleepless nights, particularly in high tech industries. However, the benefits of migration are huge and the cost of not changing equally risky. Staying with an old MES can only be a short term solution and can only lead to increasingly onerous end of life support, high maintenance, rising costs for modifications and a distinct lack of agility to meet changing production and market demands. With the correct planning and support MES migration to a modern solution that will protect the future of a business can happen smoothly.

MES Selection

As with any project, the first step of considering a MES migration is to evaluate the return on investment. Along with understanding the costs and limitations of the legacy MES, this requires a definition of the migration scope, target and strategy. The process starts with selection of the migration project team and choosing the best MES system for the application. A project team needs manufacturing and MES knowledge but should also include someone with migration experience to help foresee and resolve challenges that the project may encounter.

For system selection, shortcomings of the current MES need to be assessed and the functionality of new systems compared with the needs of the plant. The new system should have high levels of flexibility to ensure it meets future as well as current business needs. It should include modelling possibilities for materials, equipment, containers, product structures, flows, steps, data collection. There is also certainly no point in upgrading a 15 or 20 year old system to a 10 year old one. A new system should support the plant for a minimum of 10 years. The ability of a new MES to help with the actual migration process by being able to mimic the legacy MES is also a consideration.

Migration Strategies

The migration to a new system can be carried out in a number of ways, each with varying levels of risk, cost and time. These include ‘Big Bang’, Phased and Parallel approaches. Big Bang is the fastest and lowest cost option with the legacy system being turned off and the new MES turned on. This single point switch over, however, also carries the highest risk as the offline testing phase of the new system may not re-create all live conditions of the plant or cover all inter-dependencies.

Phased introduction of a new MES involves introducing the system into parts of the production process while leaving the old MES supporting other areas. These phases may be by manufacturing unit, MES function or by product lots. This approach reduces risk as confidence in the new system increases over time and parts that have been migrated can be rolled back if problems occur. This strategy does involve higher costs than the Big Bang approach, however, as routing layers and migration procedures are required to ensure the two systems work in harmony across the plant. It also costs the most in terms of time to fully implement the new system with many small migration phases.

Taking a Parallel approach puts both systems online at the same time, working in a master and slave configuration. When confidence is built that the new MES is operating successfully, it can be designated as the master and the old system switched off. This is the lowest risk approach as any problems that are encountered can be handled by the legacy MES. The time taken is also shorter than a phased approach. A parallel migration, however, carries the highest costs as synchronisation layers with orchestration logic need to be designed and implemented at application layer and, as data is duplicated in both systems, at the ETL (data extraction) routing layer.

There is no right or wrong migration strategy and the process selected is highly dependent on choosing one that fits the needs of the plant. This includes the level of risk that is acceptable and the amount of investment a business is willing to put into the project. Assessment of complexity of interdependence and interaction with other systems and applications; level of automation, and impact of downtime will also guide the choice of strategy for migration.

While each migration project has its own individual challenges and is highly dependent upon the application, in very broad terms the Big Bang approach is more suitable where there is no integrated MES (maybe a paper based system is still being used or the MES is a stand-alone application). A Phased migration may lend itself more to integrated MES with low levels of automation. A Parallel migration is a good option to consider where there is an integrated MES with high levels of automation.

Migration Planning

Whichever migration strategy is selected, the project will need to follow a number of steps. The phases of the project go through Definition, Preparation, Execution and Closure.

Definition of the migration provides the groundwork for a successful project. Steps include capturing the current system landscape, defining the future landscape and determining how the migration will happen using the selected migration strategy. The Preparation phase then covers the tasks need for the following Execution phase to go ahead. This includes activities such as configuring, modelling and customizing the new MES; adapting applications to accommodate data migration; testing and validation of the new system, and even rehearsal of the migration execution.

The Execution phase is highly dependent upon the effectiveness of the Definition and Preparation stages. It involves the roll-out of the new system as defined in earlier parts of the project, monitoring of the new system to ensure there are no glitches and shutdown of the routing and synchronization layers installed to enable the migration.

Finally, the Closure phase closes down the project and decommissions unnecessary hardware and software. It includes archiving data from the old MES and may incorporate the activation of new functionality in the installed MES.

Summary

Let’s be clear – migration to a new MES is a complex undertaking, especially in highly automated industries. Where current MES are old and present a risk to the future of a business, however, ignoring the issues they have will not make them go away. Inevitably outdated MES will need to be replaced and leaving them in place for longer simply adds to the risk and complexity of a migration project.

With the correct planning and expertise, MES migration can happen smoothly even in complex, high volume manufacturing environments. Although payback is not a short term view, modern MES systems can deliver enormous benefits to medium and long term business strategies. Their implementation should certainly be considered before legacy systems become critical and the competitiveness of a business is compromised.

For more information, please check: MES Migration Strategies white-paper

(This article was originally featured on Silicon Semiconductor)