Another approach focuses on the maintenance processes: lean project management, 5S methodology and or other organizational concepts can be of assistance.

Clients look to minimize downtimes and maximize costs reductions. In achieving these goals the technical equipment needs to be optimized. CTI Systems provides concepts and installations taking into account the following requirements:

Security of the workshop staff

Safety-relevant infrastructure should be used even in case of time pressure. Avoiding the security measurements is not a recommended solution.

Working ergonomics

Existing infrastructure should assist the operator in any situation this includes the lighting of the working place, access to various tools ie. compressed air or electrical connections and consideration of cleanliness in the workplace.

Flexibility of the infrastructure

Infrastructure of a new workshop is being designed independent of train models that will be maintained. When serving several model series there is no need to find an intermediate solution. The scope of maintenance stages and the time lapses to perform the scope play a role in the infrastructure design and influence the number of operators required. Optimizations of processes can often not take place due to the rigidity of the infrastructure.

Logistics and automation

Currently transport of spares to the work place is not organized in an automated manner. The operator currently retrieves the spare which makes for lose precious time. The availability and presentation of spares and tools should therefore be considered for an automated process.

CTI Systems' concept

Based on these new considerations CTI Systems develops, produces and delivers innovative equipment solutions that accommodate these new considerations.

The CTI concept consisted of teleplatforms (TP), CTI-Move, AGVs (automated guided vehicles), MES software systems (Manufacturing Execution System) and a WMS (Warehouse Management System).

Teleplatforms

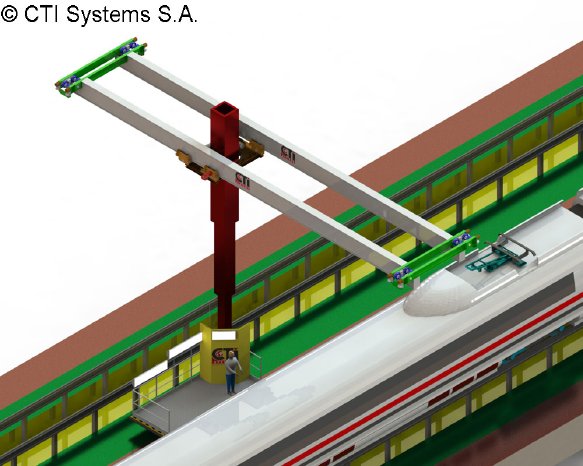

The teleplatform (as shown above) is mounted similar to an overhead crane bridge with spans of one or more tracks. It allows easy access to any position on the train regardless of design. Thanks to rotational features of the teleplatform front parts of the train are accessible.

The teleplatform is considered as a mobile workbench. The operator has at his disposal and in close proximity various hand tools. Access and connections to the tools are comfortable and properly integrated in the teleplatform. In addition, the teleplatform includes an integrated jib crane to assist the operator in lifting tasks. Spares are ordered from the warehouse by a computer placed on the teleplatform.

The teleplatform concept reduces operator's movements, increases productive working time and lower downtimes of the train maintenance.

CTI-Move

The CTI-Move offers great flexibility due to its omnidirectional drive mode which grants movements in all directions and rotation around a centre point. The platform is manoeuvred within a minimum of space and time. At the same time it offers a stable and safe working condition.

When in work position proximity smooth final position movements can be made even while the platform is in the raised position and with the platform extended granting access to hard to reach cantilevered maintenance locations.

Any train or railway vehicle can be approached quickly and safely with the most flexible access possibilities especially to the sides, nose and roof areas.

The CTI-Move is available in various models and sizes. It can also serve as a lift table to position spares in the correct position.

Automated guided vehicles (AGVs)

The use of teleplatforms and CTI-Move products the workshop floor surface remains free from guidance rails, extension cables, supports, stairs and pits therefore components can be transported from the warehouse to the point of use area on the train by an AGV. The spares transport takes place in parallel to the works on the train without any additional personal deployment.

Spares are stocked in an automated high bay warehouse. Storage and retrieval is automatic through a catalogue number. All components are managed easily and reliably.

The high degree of automation provides the most effective solution and allows for CTI's WMS and MES software connection to the client's ERP system to speed the process.

The entire concept

The following parameters are possible for workshops equipped with installations and techniques of CTI Systems:

- maintenance stages (level 1 to 5) can be carried out

- rolling stock fleet subject to maintenance is heterogeneous: carriage, double level unit trains with different number of cars, locomotives, etc.

The workshop is composed of two areas.

Area # 1 is equipped with elevated tracks. This area is generally used for regular and short downtimes requirements (up to one shift max). Processes include preventive inspections, controls, regular maintenance tasks as well as smaller repairs.

Area # 2 is on ground level. This area serves for tasks requiring longer downtimes (more than one shift), as well as for planned change-out of large components like bogies. The benefit of no pits and ramps in this area allow even heavy components to be transported by AGV.

An additional benefit of eliminating pits and elevated working platforms improves the safety aspect of the workshop:

- the entire workshop can be lightened homogenously

- no risk of tripping and falling, no need of safety handrails

Additional advantages of the CTI solution:

- less need of special tracks, i.e. for the installation of screw jacks

- shorter movement times, i.e. elimination of stairs

- increased flexibility of the work processes

- cleaner working places thanks to global surface use of cleaning machines

- real time monitoring of operations

Conclusion

Technical and organizational concepts for rail vehicle maintenance workshops offered by CTI Systems allow efficient execution of maintenance tasks on various types of vehicles. The concept considers optimal ergonomics and safety for the operators and consequently the rolling stock fleet has higher availability while maintenance costs are reduced.

Editor

CTI Systems André Weis is point-person for the railway industry. Andre offers clients with 13 years' experience in workshops for light and heavy maintenance tasks of diesel locomotives and electric trains, comfort carriages and traction units.