Hall: 10 / Stand-Nr.: C31

Coils up to 30.000 kg, vehicle engines and injection moulding tools – all of these loads are transported using special equipment that Genkinger is showing at LogiMAT (Hall 10, Stand 10C31):

- For the tough three-shift operation of an automobile manufacturer, Genkinger designed an electric seated truck with cradle whose prisms are hydraulically adjustable. This means that coils of very different diamenters can be picked-up.

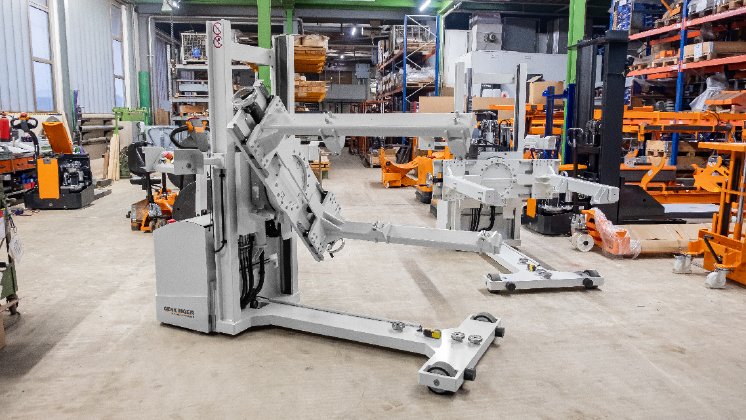

- The electric pedestrian-controlled lift truck is not only used as a transport truck; in this case it is also a working aid for the assembly of engines. The truck is guided into the assembly station of an assembly line. Once the two load handling arms have been moved together manually via the handwheel, they are finally fixed in place using four locating pins. The operator can then use two control panels to raise and lower the motor to be assembled to the most favourable position and rotate it an angle of 45 degrees.

- The electric tool changing truck must be positioned exactly vertically and horizontally to the changing table in order to exchange injection moulds weighing up to 6.000 kg. To ensure that there is no displacement during the push-pull process via a roller conveyor, the truck is docked in a form-fitting manner.

- The electric transporter Sherpa transports tools and medium-heavy parts to the production area. Genkinger has now expanded this series with modular trailers, among other things.