Halle: 3 / Stand-Nr.: 3D41

As supermarket logistics face increasing pressure to ensure quality, speed, and sustainability, the challenges are clear:

- How can storage capacity and productivity keep pace with demands for faster, more accurate deliveries?

- What solutions can address labor shortages while improving operational efficiency?

- How can rising energy costs and other expenses be mitigated to ensure profitability?

Automation: The Key to Supermarket and Cold Chain Efficiency

Automation is no longer a luxury in food retail and cold chain logistics—it’s essential for overcoming today’s challenges while ensuring sustainable, long-term growth.

Daifuku and ULMA’s solutions offer:

- Relief from labor shortages by minimizing reliance on personnel in harsh cold environments.

- Faster order processing with precision and scalability.

- Reduced food waste, thanks to enhanced inventory management and accuracy.

- Improved energy efficiency, maintaining optimal temperatures with minimal loss.

- 24/7 operational capability, ensuring consistent performance regardless of external constraints.

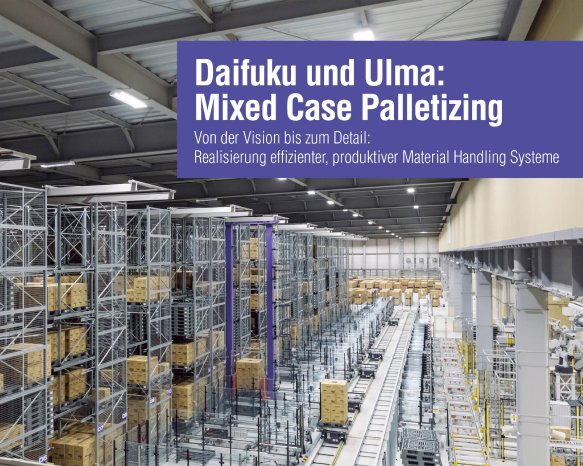

Our automation systems support the full spectrum of material handling processes, including:

- Storage replenishment

- De-palletization and collation storage

- Mixed-case palletizing

- Sequenced and grouped shipping.

Discover Proven Solutions at LogiMAT 2025

“Automation is no longer a luxury but a necessity for businesses navigating the complexities of modern supermarket logistics,” said Thomas Balluff, General Manager of Daifuku’s Europe branch. “With over 50 years of cold chain automation experience, our innovative systems are proven to solve these challenges. We invite visitors to LogiMAT to discuss their unique needs with our Daifuku and ULMA experts and discover how we can take their operations to a new level.”

Join us at Hall 3, Booth 3D41, at LogiMAT 2025 to experience the future of supermarket logistics firsthand.

About ULMA Handling Systems

ULMA Handling Systems is a leader in automated intralogistics solutions that harmoniously and globally connect all aspects of an automated storage and order-picking project. Its focus is the design, manufacture and implementation of systems and equipment for the handling and transport of goods in warehouses and distribution centres in all types of industrial sectors. ULMA Handling Systems, present in Europe and Latin America, has the permanent collaboration of the world leader in the sector, the Japanese company DAIFUKU. It also develops integral baggage handling systems for the Baggage Handling sector, backed by extensive experience in the sector, and an extensive range of products and modular solutions that adapt to the functional needs of any airport.