Constructing - nesting - laser cutting using industrial robots

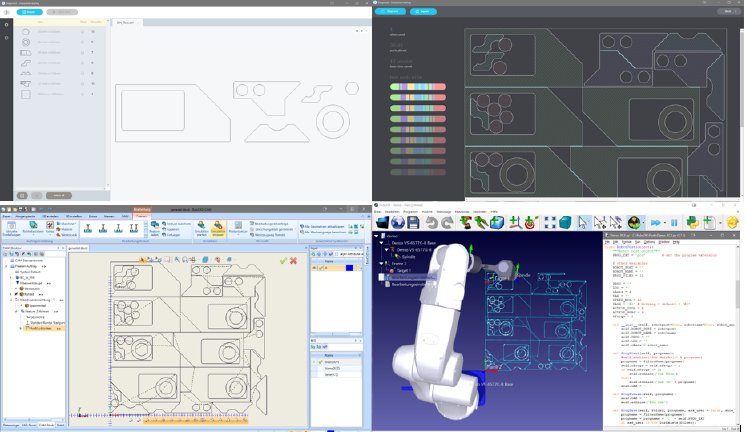

BobCAD-CAM, Deepnest and RoboDK support the user with powerful functions for the cost-effective creation of NC programs and the simulation of robot movements when using industrial robots in modern manufacturing. With BobCAD-CAM CAD models are designed, with BobCAD-FreeCAD even free of charge. The constructed parts can then be passed to Deepnest for nesting. The optimized nesting plan created by Deepnest is then handed back to BobCAD-CAM, where the specific CNC programs are generated which are required for the desired production type. After transferring the NC data to RoboDK, they are converted into robot programs which calculate and simulate the robot movements.

The programs in detail

Deepnest for the economical nesting of components

Deepnest is a free nesting application which is perfectly suited for laser cutters, plasma cutters, and other CNC machines.

Deepnest nests part layouts in a tightest possible area in order to gain optimum use of the material and save processing time. Common lines between two components are automatically merged so that the laser does not have to cut the same path twice. This does not only save time, but also improves the quality of the parts because heat distortion from multiple laser passes is prevented.

Deepnest uses state-of-the-art part layout technology with part-in-part placement and the ability to nest bitmap images for laser engraving.

BobCAD-CAM for part design and NC programming

From CAD parts to simple 2-axis NC programs and complex programming of 5-axis toolpaths: BobCAD-CAM provides the necessary tools. Powerful machining strategies in BobCAD-CAM allow for simple and error-free programming of demanding NC programs. The user has various wizards available to help him with programming. The intuitive user interface of BobCAD-CAM, allows for a quick introduction into the program without costly and time-consuming training. BobCAD-CAM offers inexpensive modules for 2 ½ - 5 axis milling, turning, turn-milling for machining centers, routers, laser, plasma and water jet cutting, and wire EDM. An add-on is also available for engraving and embossing artistic contours.

Programming and simulating industrial robots with RoboDK

With RoboDK industrial robots can easily be simulated and programmed offline. With RoboDK, the robotic arm is used like a 5-axis milling machine (CNC). An extensive library of industrial robot arms, external axes and tools simplifies the programming of robot applications enormously. The manufacturer-specific programming of the robots is no longer necessary. By programming the robots outside the production environment, production downtimes which will occur during workshop programming can be avoided.

BobCAD-CAM, Deepnest and RoboDK together as a team

RoboDK can be used to program robots like CNC machines. If it is necessary to place components on plates, Deepnest takes over this task and ensures effective, automatic nesting of the components. NC programs created in BobCAD-CAM or externally can be imported into RoboDK for robot machining. RoboDK automatically generates error-free tool paths, optimizes the robot path and avoids singularities, axis limitations and collisions.

United in productivity and profitability

BobCAD-CAM, Deepnest and RoboDK complement each other perfectly when programming machining processes using robots in production.

BobCAD-CAM is available as a stand-alone CAD-CAM system and as an add-in for SolidWorks. Deepnest is available for Windows, OSX and Linux. RoboDK versions are available for Windows, Mac, Linux and Android.

Those interested in trying out BobCAD-CAM, Deepnest, RoboDK can download the programs and obtain a trial license.