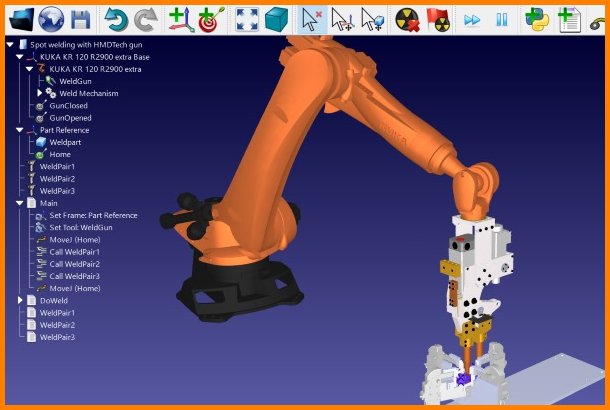

RoboDK is a powerful and inexpensive tool for the simulation and programming of industrial robots.

RoboDK allows for simple simulation and offline programming of industrial robots. The programming of robot applications is enormously simplified by providing access to an extensive library of industrial robot arms, external axes and tools. Therefore, users do not need to learn manufacturer-specific programming anymore. RoboDK is suitable for almost every type of application, such as milling and drilling, welding, cutting, painting and inspection.

Simulate and program in 5 steps

Select robot - define tool - load 3D model - simulate tool path - generate robot programs

This is all you need. The RoboDK postprocessors support more than 70 robot controllers, including ABB RAPID, FANUC LS, KUKA, Universal Robots.

The best thing about RoboDK

- Thanks to the intuitive user interface of RoboDK, programming knowledge is not necessary.

- Every robot can be programmed offline with just a few clicks.

- RoboDK has an extensive library with over 500 robot arms

At RoboDK, robots are programmed outside of the production environment. This avoids production downtimes caused by workshop programming.

Using simulation and offline programming, several scenarios of a manufacturing cell can be examined before it is set up. As a result, errors that are often made during installation are recognized early and avoided.

RoboDK versions are available for Windows, Mac, Linux and Android.

Interested parties who would like to try out RoboDK can use the program download and get a trial license.