The software of professional measuring devices is not always easy to operate. Various parameters must be set accurately to obtain valid and reliable measurement results. However, to do so, operators are often confronted with too many settings and choices. But this does not have to be the case: versatile and highly precise measuring devices can indeed be operated easily and intuitively. The measuring instrument manufacturer DataPhysics Instruments from Germany proves this with its latest product release: the dpiMAX software for the contact angle meters of the OCA-series.

Daniel Scholz, product manager for the dpiMAX software at DataPhysics Instruments, explains: “The continued development of our previous device software had been leading, over time, to an expert software with many options to choose from. However, this large selection of options also made the software more complicated. Based on this knowledge, our new software dpiMAX focuses primarily on easy and straightforward usability. In addition, numerous technical innovations have been implemented, so that we can now offer our customers a comfortable state-of-the-art software solution.”

Focussing on the needs of the operators already in early development stages, the dpiMAX software was designed using an agile approach. The proficient software development team at DataPhysics Instruments was able to build on its decades of expertise with measuring device software as well as on state-of-the-art development tools. Scholz says: “Our guiding development principle was to ensure simple and intuitive usability, which enables anyone to perform measurements quickly and conveniently. According to feedback from our pilot customers, we have achieved our goal.”

dpiMAX accompanies its operators through the entire workflow

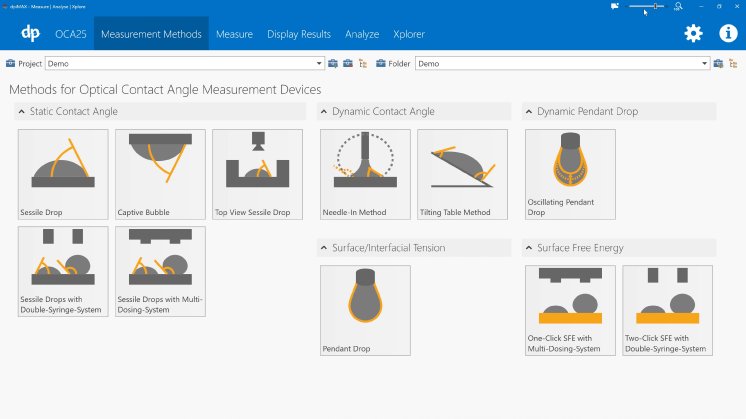

True to the name-giving motto of dpiMAX – Measure quickly, Analyse easily & Xplore intuitively – the software accompanies its operators step by step from the device settings, through the measurement and evaluation, to the creation of reports and the presentation of the measurement results. Thus, beginners are guided comfortably through the entire process. Of course, adjusting additional settings individually is still possible for experienced operators, when facing complex measurements. This applies, for example, to advanced camera settings, which can be utilised to optimise difficult image situations. In sum, an intuitive operation is ensured for every operator, regardless of their level of experience.

Well-organised user interface facilitates focussed work

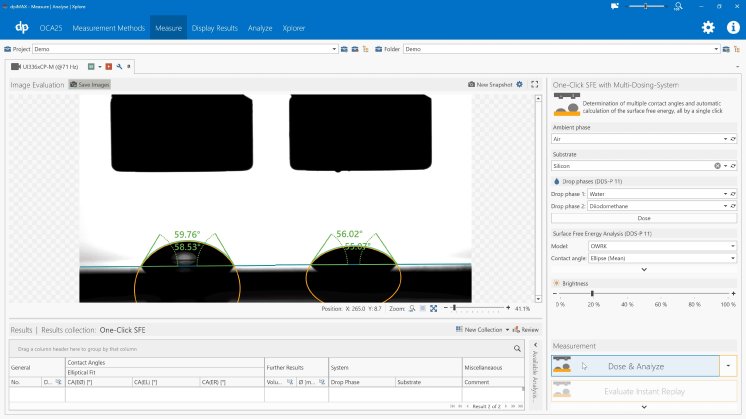

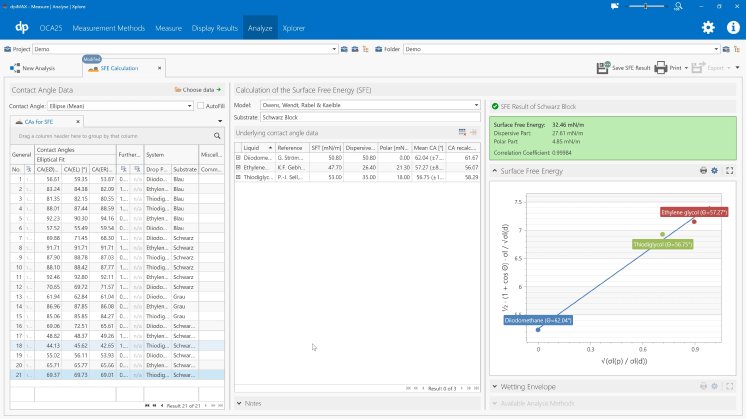

dpiMAX supports focussed work by displaying only relevant information on the well-organised user interface. During a measurement, for example, the user interface shows the drop image, the results table, and a customised control panel, which contains only the parameters and control elements required for the selected measurement method. Results are always seen at a glance. For example, the contact angle is displayed directly at the three-phase point in the drop image. The analysis of the surface energy additionally contains an easy-to-read colour code: the colour directly indicates how robust the obtained result is. Hence, thanks to the clear display, operators can easily stay focused on the essentials.

Additional smart functions make measuring easy and convenient

The innovative dpiMAX software not only performs basic tasks, such as controlling the measuring device and executing analysis algorithms. It supports its operators far beyond that, among other things with additional smart functions, which make measuring particularly easy and convenient.

This way, the drop shape evaluation is done in no time: dpiMAX immediately evaluates the surface tension of a hanging drop, or the contact angle of a sessile drop, and directly displays the result in the live camera view. In addition, videos can be recorded and evaluated subsequently. But even if the operator forgets to start recording, the measurement is not lost thanks to the special Instant-Replay-function. dpiMAX always saves the last seconds of the camera image so that it is easy to “rewind” to a specific image situation.

The dpiMAX software also allows to carry out predefined processes as simple one-click measurements, which is particularly convenient when the operator has to conduct repetitive measurements. In addition, dpiMAX reminds the operator with smart hints to input necessary information on material specifications and suggests suitable dispensing needles when measuring the interfacial tension.

Adaptability to individual preferences

dpiMAX not only offers a host of useful functions, which make measuring and evaluating straightforward and even fun. dpiMAX is also available in several languages, making it easy to use for operators all over the world. Furthermore, operators can set substances as their personal favourites and add substance names commonly used in their laboratory. It is even possible to adapt the user interface of the dpiMAX software to different screen sizes, thanks to an integrated zoom function.

dpiMAX is compatible with all current contact angle meters of the OCA series from DataPhysics Instruments and is available as of now. The software is modular in design, so that the methods and analyses required by each operator can be put together individually. Hence, the application experts at DataPhysics Instruments will be happy to offer customised packages. In addition, existing customers with OCA-devices can currently buy an upgrade to dpiMAX at favourable conditions.

The new dpiMAX software from DataPhysics Instruments supports in a unique manner the realisation of high sample throughputs, the investigation of surface properties of new materials and the development of innovative products. This makes dpiMAX a valuable asset for research laboratories as well as quality and development departments all over the world.

About the contact angle meters of the OCA-series

All contact angle meters of the OCA-series are characterised by high-quality optics, accurate dosing and precise sample positioning. The OCA-series includes several models, which all allow measurements according to a wide range of international standards.

The entry-level model OCA 15EC has a powerful camera lens with 6.5x zoom and a sample stage, which is mounted on a magnetic base and can be positioned freely in x- and y-direction.

The standard model OCA 25 has a sample stage that can be moved in all three spatial directions via a precision mechanism. The model is compatible with the nanolitre dosing system, the electronic direct dosing system DDE/x for positioning up to four syringes as well as with electrical thermostatic devices, such as a sample chamber for temperatures of up to 700 °C. Special variants of the OCA 25 are built for measurements at pressures up to 750 bar and temperatures up to 1800 °C.

In the premium model OCA 50, the sample stage is mounted on motorised axes and can be conveniently positioned with an external control unit. Hence, surface parameters, such as the surface energy of a solid, can also be determined fully automated.

The expert model OCA 200 is the top-tier-device from DataPhysics Instruments: it has an extremely powerful camera lens with 10x zoom and is compatible with the picolitre dosing system PDDS. This enables measurements on macroscopic as well as microscopic structures, for example in the threads of dental implants or on the metal struts of coronary stents.

If this press release is reprinted, we would be pleased to receive a copy.