In doing so, DATRON AG sets new standards in the competitive class of remote-controlled glider models with a span of three meters (F3B). At the same time, the innovative machine builder proves to be a supplier of high-tech products that are ideally suited for prototyping and mold making. The result can be seen with the naked eye: DATRON customers receive high-precision with virtually no need for rework resulting in highly sophisticated components.

On a smaller scale DATRON offers the revolutionary 3-axis milling machine DATRON neo, which recently celebrated its official world premiere at the AMB in Stuttgart and IMTS in Chicago, an innovative product solution for small series and prototype construction. Based on the Plug & Play principle, the compact all-round talent can be controlled via the brand-new DATRON next software, even without years of milling experience, and enables the easiest access to high-speed CNC milling.

About the competition:

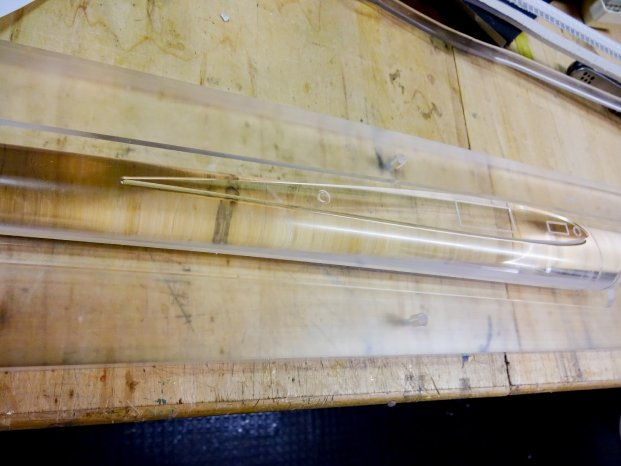

The Lippenweide Trophy is a partial contest of the F3B World Cup World Cup FAI organized by the FAI. In this competition the three disciplines of thermal flight, route and speed are to be completed with a glider model. This requires aerodynamically highly sophisticated flight models, which require very high precision and stability at a very low weight, since the flight tasks partly contradict in their requirements. In the case of speed flight, for example, forces of up to 30 times of gravitational acceleration impact the model.