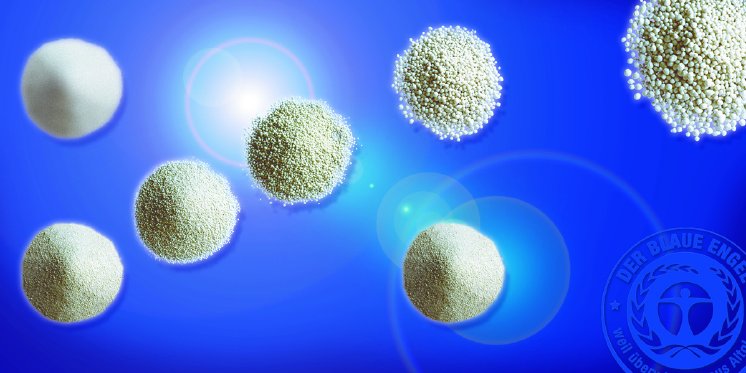

The HSP technology in combination with the surface structure and grain form of the lightweight filler PORAVER leads to low-shrinking easy to handle mortar systems with outstanding mechanical properties.

In conventional cellar renovation, after the horizontal damp proof barrier is carried out, a variety of different working steps and the use of a range of different materials are still necessary. The usual work process, including the intermediate drying times, requires about four working days. When the Hahne system solution "INTRASIT" is used only four hours are needed to achieve the same result.

Linked to the substantial improvement in time are significant work facilitations. For example, a plaster surface of 40 m² and a coat thickness of 2 cm needs only 520 kg climate plaster. With traditional restoration plaster it would be 1040 kg - 100% more than in INTRASIT RZ2, which also yields a pronounced anti-mold effect.

"First field tests" to further development of the highquality building protection systems were carried out, among other things, with the restoration work on the former post office of Thurn and Taxis in Lieser in the Middle Moselle under the expert leadership of Mr.

Wichmann, executive of the R+D department at the Heinrich Hahne GmbH & Co. KG. In this location requisite exterior, interior and cellar retrofits have been planned and reviewed over the years. The historical and cultural monument dated back to the year 1517 and is the oldest part of the former postal Court of Thurn and Taxis in Lieser in the Middle Moselle. Until a few years ago the preservation of the building proved to be particularly difficult because the object had been exposed to the Moselle high waters. Because of the new high water protection measures in embankments, floods are a thing of the past.

Due to the good experience with the Poraver enhanced renovation products, thermal heat insulation measures like filling in the gaps in the wooden ceiling beams, were done with Poraver-fills.