"In this respect we have a wide variety of opportunities to create value-adding refinements to the product and make it stand out from its competitors", explained Achim Kurreck, Managing Director of H.C. Moog GmbH. In his role he works with every type of product packaging and is therefore able to observe the market trends. For many decades his machine engineering company has been developing and building sheet-fed gravure printing presses for the production of high-quality packaging materials. Despite the global predominance of offset printing to produce packaging and high-finish printing, this family-run business from Hessen in Germany has cornered a niche market as the specialist in sheet-fed gravure printing.

But what actually is gravure printing? Gravure printing means that the printing elements are in the form of etched depressions - known as cells - nowadays generally produced by laser onto the printing form (cylinder or polymer plate). Before printing, the entire printing form is dipped into the ink bath, and excess ink at the surface of the print cylinder is then removed by a doctor blade. Only the ink for printing remains on the cells. The impression roller then presses the material which is to be printed (paper, cardboard or film) onto the image carrier. The contact pressure and force of adhesion transfer the ink to the material. The depth and screen width of the cells define the colour intensity; the graphic quality is excellent and in high resolution.

"For many applications the industrial sheet-fed gravure printing process is very straightforward compared with other processes," explained Achim Kurreck, who views this printing technology principally as an ideal, cost-effective process for producing very high-quality product packaging. Since the end of 2011 a Moog gravure printing press has been in production at Amcor Tobacco Packaging in Switzerland - a global player in the responsible packaging market. It produces cost-efficient, quality mock-ups and short print runs in excellent print quality.

The latest MOOG1 TBR Compact 740/1040 is a multi-functional machine providing the maximum sheet format of 740 x 1040 mm, and a maximum output of 12,000 sheets per hour. It permits sheet-fed gravure printing on conventional gravure cylinders as well as on digital photo-polymer plates. "All our experience gained from sheet-fed gravure printing is incorporated into this new design," stressed Achim Kurreck. "The core piece of the machine, the double-circumference impression roller, is made from high-quality casting. This means that we were able to raise the linear pressure for embossing a little higher without having a negative effect on the machine's service life.

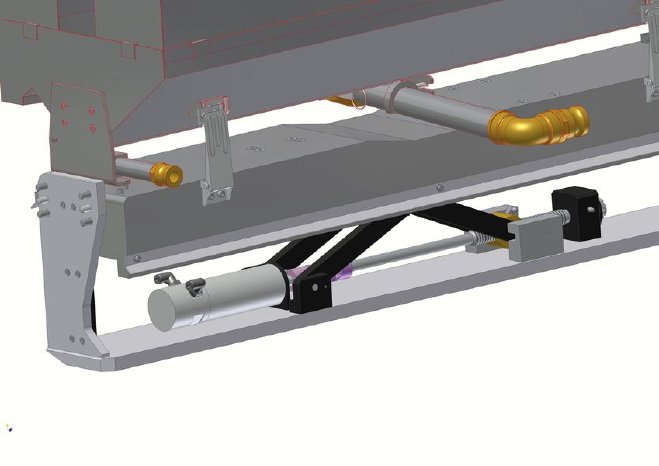

The gravure specialists designed new ink sumps to transfer the ink to the print cylinder. There are three types available for different ink quantities. "We achieve the optimum mixture with minimum ink quantities, which makes the products more environmentally sustainable when recycled, while also reducing printing costs," said Achim Kurreck, as he outlined the positive features. To adjust the height of the ink sumps, the manufacturer needed a drive that can be deployed in a potentially explosive atmosphere.

The choice they made was an air motor from DEPRAG SCHULZ GMBH u. CO from Amberg. A 400 watt BASIC LINE vane motor was installed on the ink sump at the very heart of the printing mechanism. With a nominal speed rating of 60 rpm and a basic torque of 63.6 Nm it adjusts the height of the ink sump.

An air vane motor operates on a very simple principle. The compressed air by which it operates sets in motion the rotor which rotates inside an eccentric cylinder. Vanes are inserted into the slots of the rotor and the centrifugal force that arises presses them against the cylinder wall. This creates work chambers for the expanding compressed air. As a consequence, as it expands, the compressed air converts the pressure energy into kinetic energy - causing rotational motion. Since the air is not under stress the vane motor remains cool, so cannot overheat. Compressed air is an intrinsically unproblematic energy resource - there are no hazards created by electrical contacts and leads. DEPRAG's Product Manager, Dagmar Dübbelde, said: "That is the reason why our air vane motors are deployed in potentially explosive areas."

All the BASIC LINE air motors with their robust grey cast housings are ATEX-approved as standard for use in potentially explosive atmospheres. "So we did not need to spend additional time or money getting ATEX compliance," said Moog's Managing Director Kurreck, outlining one of the outstanding features that persuaded them to opt for the DEPRAG air motor. The air motor's power density also helped with the decision.

Many other plus points spoke in favour of the choice. The main one was its high power density. Depending on the version, the motor requires only a fifth of the mass of an electric motor and is a third of its size. Output from air motors is almost constant over a wide range of speeds. This means they can operate optimally within a wide range of changing loads. Motor power is controlled by continually throttling the air quantity. The motor is never overloaded. It sustains the load down to standstill without causing any damage and will then restart without problem - any number of times in succession. With their many design variants, their straightforward, well proven construction, their low intrinsic weight, wide range of speeds and their explosion safety, DEPRAG air motors can be used in a broad range of applications.

Yet the DEPRAG motor had even more features that convinced the engineers at Moog. Air vane motors are fully robust and low on maintenance. The only parts that need replacing at specified intervals are the vanes. And when this is necessary, the maintenance engineers do not have to dismantle the air motor. Dagmar Dübbelde explained: "Our BASIC LINE air motors have a patented vane exchange system which means they can be replaced in just a few minutes." The air motor remains in its assembled position while the vanes are replaced - saving valuable time. Once the screws have been loosened and the roller removed, tweezers are used to quickly and easily remove the vanes and insert new ones.

Achim Kurreck places high value on the level of cooperation with DEPRAG's customer advice and service. And that was another reason for equipping the new MOOG1 TBR Compact with the robust DEPRAG air motor. "In the interest of our customers we place great value on using quality German products with the corresponding guarantees as well as the possibility of using spare parts of the same construction.

According to the experts at H.C. Moog, sheet-fed gravure printing is the ideal printing process for printing the exclusive, high-quality packaging that is in demand on today's market. Achim Kurreck: "Gravure printing is the only process which guarantees stable production at constant high quality." An ingenious inline viscosity meter inside the innovative ink-sheet-fed gravure printing press takes care of that. It ensures consistent viscosity throughout the print run. Since a print cylinder or a unique polymer plate is prepared specifically for each printed product and used as the image carrier, the cell configuration is adjusted to the printed material and the amount of colour pigment to be transferred. According to Achim Kurreck that ensures a constantly high level. "No unknown parameters can have a negative influence on the results."

Once printed, the freshly-printed sheets move on to the dryer. Here too H.C. Moog has forged new paths with its ink-gravure machine. The drying process is controlled from the machine's control console. The sheets are dried by frequency-controlled radial blowers and heating cartridges which can be adjusted to the requirements of the substrate. Immediately after the print zone the ink on the sheets is dried at normal room temperature by high speed air knives (HAK) which can be controlled for pressure and air flow. The sheets then continue to pass through three further cassette combination dryers. Another HAK collects the exhaust air between the first and second cassettes, and the recovered energy is economically reused. Achim Kurreck: "This saves resources and makes a positive difference to the overall financial considerations."

The ingenious MOOG1 TBR Compact 740/1040 is suitable as a stand-alone production machine because it can handle several passes without problem, but is also very useful as a pre- or post-processing machine in an offline combination with other sheet-fed printing presses. As opposed to rotogravure printing there is no need to adjust the cylinder diameter. "This minimises costs, since it can print any size of pack that fits into the 740 x 1040 mm format", explained Achim Kurreck. By using photopolymer plates it is possible always to use the same plate dimension. Kurreck: "This means that it can even print quite challenging short runs extremely efficiently and with exquisite results."

Many industry sectors opt for unusual and offbeat designs to arouse consumer interest in their products. The refined techniques of sheet-fed printing and the capacity to make use of bronzes or inks with metallic pigments are a sign of the high quality of the product, and are popular with customers. The machine is capable of printing on paper and card, as well as non-stretch films, along with many other substrates. And the MOOG1 TBR Compact has no problem with "security printing" to protect products from counterfeiting. "With our latest state-of-the-art machine we are affirming and expanding our market lead in sheet-fed printing presses," said Moog's Managing Director Kurreck, as he looks optimistically ahead into the future of the family-run printing press manufacturer, based in Rüdesheim on the Rhine.