The challenges of automated screw assembly

Screw assembly is prevalent in all production industries. In essence, the process creates a secure connection between two or more parts, using one or more screws. What initially sounds simple, is in practice extremely complex due to the wide range of variances, such as position, angle and manufacturing tolerances. Using conventional automation, it is usually complicated and expensive.

DEPRAG has teamed up with Micropsi Industries in order to meet the challenges involved in automating screwdriving processes. DEPRAG is an established and experienced manufacturer of screwdriving systems, special machines, robot cells and assembly systems for customers from various industries including manufacturers from the automotive, household goods and electrical industries.

"We are pleased to be in cooperation with such a traditional manufacturer as DEPRAG and to be able to profit from their enormous wealth of experience in the field of screwdriving technology", Dominik Bösl, CTO of Micropsi Industries commented on the cooperation. "This joint solution is taking on a cross-industry challenge: screw assembly. The cooperation provides our customers with a robust and profitable automation solution, advancing our goal to simplify access to automation".

AI-based screwdriving solution overcomes variances

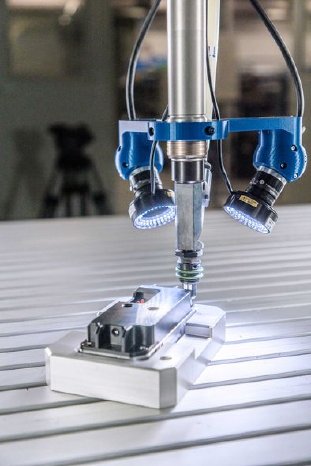

The cooperation brings DEPRAG's screwdriving technology and Micropsi Industries’ MIRAI robot control system together. By using artificial intelligence, MIRAI-controlled robots can reliably manage complex production tasks which were previously either not possible, very complicated or unprofitable to automate. A MIRAI-guided robot can react to its working environment and correct its movements in real time.

"The intelligent controller MIRAI from Micropsi Industries is an ideal extension to our automation portfolio", explains Daniel Guttenberger, Screwdriving and Feeding Technology Product Manager at DEPRAG. "At the heart of our company philosophy is our pledge to always offer our customers the best quality and most innovative products. Technologies such as MIRAI allow us to react to the current challenges of our customers and support them with competitive solutions long-term".

The intelligent screwdriving solution from DEPRAG and Micropsi Industries means that position and angle tolerances, as well as production tolerances can be compensated on the component. Dynamic tasks on a moving belt can also be mastered for the first time. The solution is suitable for the assembly of a wide range of products and components for example, household appliances, electronics, automotive parts, agricultural machines and much more.

About Micropsi Industries

Micropsi Industries is a VC-backed robotics software company with offices in Berlin (R&D) and San Francisco. Founded in 2014, the company is at the forefront of innovation in robotic automation, with particular focus on assembly tasks. Further information can be found on their website: micropsi-industries.com