As early as the 1980s DEPRAG SCHULZ GMBH u. CO, the screwdriving system specialist based in Amberg, was already tackling this problem. And with success! The machine tool builders were supplying renowned US manufacturers with screwdriving systems for diskette drive assembly units. "Assembly conditions corresponded more or less to sterile room requirements" recalled Hierold. "That was a challenge for us as machine tool makers." The fact that all the components could be harmonised with one another because they all came from a single source, proved to be an advantage. The one-stop-shop company convinced its customers with its high-quality, well balanced departments, all of which had a single aim - to prevent any abrasion as the fasteners were fed into the screwdriving system, and during the actual fastening process.

When cleanliness during assembly is required, the entire screwdriving process must come under the microscope. Jürgen Hierold said: "Every step from planning, to production and assembly must be carefully examined." The first thing is to obtain an accurate definition of the cleanliness requirements for the product in question. Only in cooperation with the design engineers, the production, logistics and quality management department is it possible to achieve the highest possible level of technical cleanliness and thus reliability. Trained staff are just as important as a clean production environment. It has mostly proved to be unnecessary to set up high-cost sterile-room conditions with the air conditioning and particle filtering systems entailed. The crucial point is that the clean room should be maintained in a non-critical state of cleanliness. The principal thing is to prevent disruptive particles from being brought in by people, materials or transport systems.

Contamination of components by particles of dirt can be prevented as early as the design stage. In their designs, engineers should avoid corners and edges where dirt can be trapped, and which are hard to clean. Rounded edges are easier to keep free of particles. At the screw location, drilled through-holes instead of blind holes are easier to keep clean. Jürgen Hierold said: "Equally, appropriate cleaning processes are the foundation of preparing the clean-room, such as using specially treated fasteners." For example, with its Cleancon® service, the well-known manufacturer of threaded fasteners, Arnold, offers fasteners that in their manufacturing process, cleaning and packaging are designed specifically to meet the demands of technical cleanliness in the screwdriving process

But investigations show that the screwdriving assembly process itself can also produce hazardous particles caused by friction. Alternative materials and processes can counteract this. Jürgen Hierold explained: "If I use uncoated aluminium or untreated steel for the assembly unit, I am simply opening the door to particle contamination caused by friction or corrosion. Choosing alternative materials such as polished stainless steel and eloxated aluminium will reduce the number of such particles and each component of the assembly system is much easier to clean."

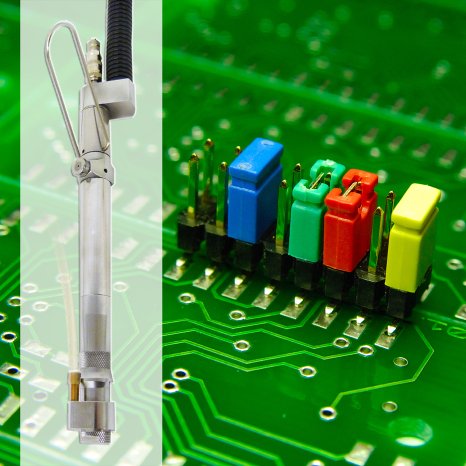

If a pneumatic screwdriver is required in the production plant design, that too must meet the cleanliness criteria. DEPRAG's standard range contains pneumatic screwdrivers suitable for sterile rooms, with polished stainless steel housings and controlled exhaust air extraction, which we recommend for assembling screws inside a clean room. Jürgen Hierold emphasised: "Such high-quality industrial screwdrivers are ideally adapted to the high cleanliness requirements, and have proven themselves many times."

Likewise, the number of particles can also be greatly reduced as the fasteners are separated from one another, by choosing the right technology. Standard vibration feeder/conveyor move the screws by creating a throwing motion inside the conveyor hopper. The screws rub against one another and harmful particles are caused by this abrasive action. Jürgen Hierold said: "If technical cleanliness is paramount we recommend that parts should be fed gently using a feed system that employs an oscillating rail segment (Sword Feeder)."

If the screw is fed to a position directly above the screw hole in the component, contamination by particles is not necessarily prevented. "It is better to look for alternatives", stressed the expert. The feeder system works cleanly and reliably by having the screwdriver travel to a specified position above a vacuum source. A blast of air shoots the required screw into position for the next screwdriving operation. Any particles of contamination that may occur during the process are picked up by the vacuum. Only then does the screwdriver travel back to the "screwing position" and the screw is fitted. "Vacuum sources at every relevant position increase cleanliness and are recommended at every point where abrasion or friction can occur", stated DEPRAG Sales Manager Hierold.

And Mr. Hierold has his sights on even more assembly processes. If the screwdriver bit does not mate accurately into the screw drive, unwanted particles are caused by the abrasion. The DEPRAG MINIMAT-EC-SERVO range of screwdrivers reduce their speed as they engage with the screw. The integral sensor system assists with recognising the precise position of the screwdriver and ensures that the bit engages properly into the screw drive head. Only once the bit is correctly engaged into the head does the speed ramp up to carry out the fastening action. This prevents bit slippage and particle contamination.

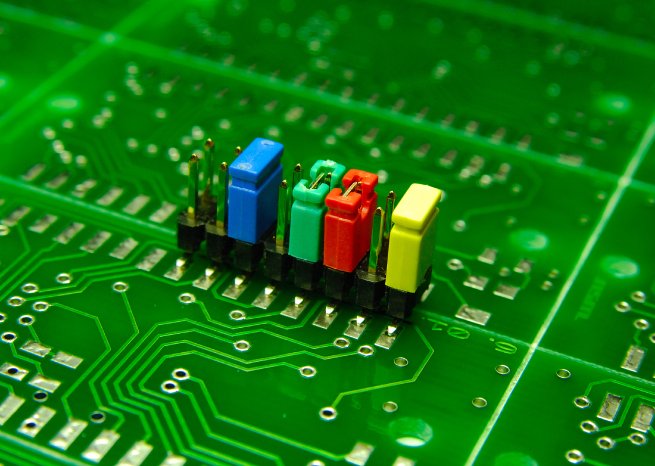

Using cover stencils and screw templates during the production process reduces the chance that hazardous particles make their way to the assembly part and also assist with ESD protection. Electrostatic discharge generated on assembly components during the process is conducted away and hazardous contamination particles are captured by the template cover. Jürgen Hierold said: "By bundling this complete package of different counter measures we minimise the build-up of particles.

So he recommends that when plant engineers need to create clean room production facilities they should choose a machine tool builder that offers every key aspect of screwdriving systems from their own range of manufactured tools. "It's the best way of ensuring that each component and each process, such as feeding, positioning, and screwdriving is harmonised to the others. The entire process can be examined, evaluated and enhanced with technical cleanliness in view."

Miniaturisation in technology is coming on at pace. Technical cleanliness in the production process is a burning topic and has become a quality characteristic. What in the automotive and computer sectors is standard for the more sensitive parts of the product, is now concerning suppliers and other industries too. If you can comply with the high cleanliness requirements, you have good opportunities in the market. Said Jürgen Hierold: "The specialists at DEPRAG are ready for the future. We canI produce the solution."