Manual work stations are flexible and can be adapted to any order situation: during the lean times production can be reduced without problems with high system amortisation payments, in the good times there are no limits with the option of expansion by adding manual work stations. This flexibility has caused the upwards trend in manual assembly processes. The status of today's technology is that the required high quality standards and production rates with intelligent manual work stations is just as guaranteed as with fully automatic assembly systems. With regard to processing reliability there is nothing better than an automatic assembly system "the high level of processing reliability however can only be attained if all components of a manual work station are coordinated with one another and certain core requirements have been considered", emphasises Jürgen Hierold, Sales Manager at DEPRAG SCHULZ GMBH u. CO. The specialists for screwdriving technology have a comprehensive range of sophisticated standard modules with manual work stations which can be created to be reliable, economic and ergonomic. At the trade fair MOTEK 2014 the company from Amberg, Germany presents a new item from their programme of intelligent manual work stations, the DEPRAG Feed Module (DFM). This new screwdriving unit further increases processing reliability in the industrial assembly of serial products and optimises cycle times. On their stand 1650 in hall 1 DEPRAG presents a complete designed manual work station as well as two exhibits of screw and nut applications which can be used to display the advantageous functions of the new DEPRAG product.

Automatic feed motion and adjustment

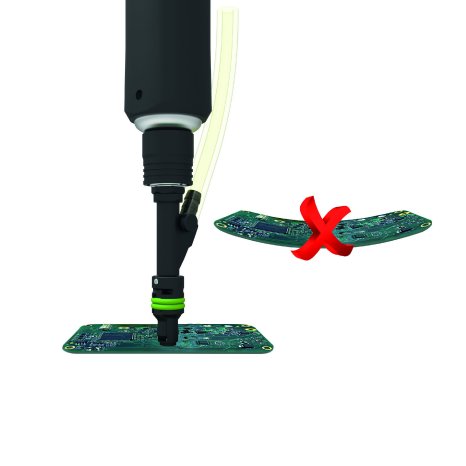

The DEPRAG Feed Module facilitates the screw assembly of components with complicated external geometries such as rounded housings and difficult to reach screw positions such as deep screw holes. Using intelligent manual work stations the screw feeding is automatic using vibratory spiral bowls or sword feeders so that similar cycle times and production rates can be achieved as with automatic assembly processes. Thanks to the automatic supply of joining elements from the screwdriver one hand of the operator remains free and can be used for other actions. In automatic screw feeding in many cases joining elements can only be adjusted or positioned with difficulty- often templates are required which the operator must hold as well as the screwdriver. With the DFM the screwdriver has its own feed motion with vacuum support. The automatically fed screw is held with a vacuum sleeve, positioned and directed and it can therefore reach deep and difficult to reach screw positions. "The vacuum support and automatic feed motion are the main features of our new DFM. The operator can easily reach critical screw positions", explains Jürgen Hierold.

Even components which require a nut rather than a screw as the joining element can be fed and assembled reliably with the DEPRAG Feed Module. The Sales Manger added: "For DEPRAG this is a real first. For the first time we can offer manual nut feeding with the DFM". An integrated stroke mechanism via cylinder controls the precise pressure on the joining element, the screw or nut. The feed stroke can be set according to the pressure required and thereby the same pressure is always applied to the components during assembly, it is not dependent from the physique and condition of the operator. The force for the stroke is precisely defined and automatically controlled by the Feed Module. Pressure sensitive components such as circuit boards can therefore be handled delicately and the operator is relieved in regards to pressure and motion processes. "Our new module increases not only the processing reliability but also an important contribution to the ergonomics. The operator is relieved from certain hand movement and pressure forces", said Jürgen Hierold. As well as fatigue-free work, the exact positioning of joining elements and the individual control of pressure, the DEPRAG Feed Module also offers further advantages. Simple bit exchange via a toolbox and a screwdriver with quick change chuck for varying joining elements on one component. And manual work stations already installed can also be simply and easily updated with the new module.

Additional functions for more stability during processing

The DEPRAG Feed Module is a piece of screwdriving equipment made up predominately of a screwdriver, stroke unit, feeder and device for screwdriver guidance, such as a stand mounted on the work station or a portal installed by the operator. The DFM can be combined with pneumatic as well as electric or sensor controlled EC screwdrivers. A manual work station equipped with a DFM can utilise a screwdriver with LED status display on the handle so that the operator can immediately see a current status report of the successful screw assembly. Upon request the module can be fitted with a rotating handle, in this way screw assemblies can be reached more easily which would require various opening directions of nosepieces. The nosepieces hold the screw in position. In tight spaces or for difficult to access screw positions the rotation can be an important function e.g. for 90 degree elongated assembly holes.

Another option is the programmable pressure - however this is only available on stands or portal solutions with the positioning control system. Stands or portals help the screwdriving tool to be guided securely to the screw position. This is an important contribution to the ergonomics of the manual work station: They give the operator the option to move the screwdriving tool three dimensionally. The torque reaction in the assembly torque does not affect the operator's hand but instead is absorbed by the portal or stand. The positioning control system ensures that the suitable joining element is assembled on the exact location, at the correct time and with the ideal torque. "Individual screw tightening parameters can be set for each screw position using an additional positioning control system. This feature adds to the processing reliability", confirms Jürgen Hierold.

One stop shop

The new DEPRAG Feed Module adds another component to the portfolio of the German screwdriving specialists, enabling more processing reliability, flexibility and ergonomic work in the assembly industry. "We are a complete solution provider, providing all components of the intelligent manual workstation from one company and all coordinated with one another", said Jürgen Hierold. "Only in this way can processing reliability be guaranteed". All modules of the manual work station come from our in-house production: screwdriver, feeder, controller and process monitoring are all coordinated. DEPRAG uses standard components from their own programme to allow an individual assembly system design. Between the individual components of the manual work station such as screwdriving controller and feeding technology and screwdriver are mechanical control technical interfaces. With a complete solution provider like DEPRAG these interfaces are compatible with each other from the start and no time and effort is required to make adjustments so they can work together.

From the start the customer has just one contact person. Reduced delivery times due to standard components, rationalisation effects due to in-house production of components as well as the elimination of complicated interface descriptions all increase the economic viability of such a new investment. The requirement for technical cleanliness and ESD capability are also realised throughout all individual components of the DEPRAG manual work station. Intelligent manual work stations combine manual work with the high processing reliability of automated assembly as a solution from one single provider.