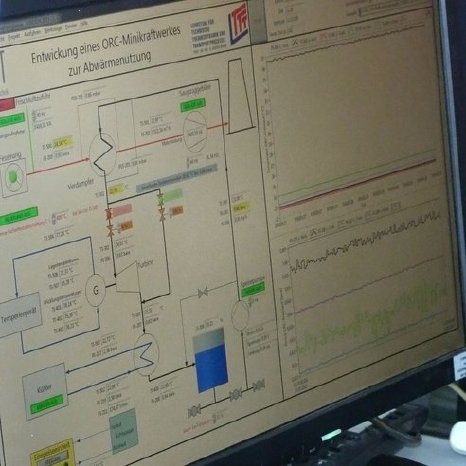

The basic idea: "In many industrial activities process gas is lost into the atmosphere. The original plan was to find a way to utilise the potential of these gases", explains DEPRAG Chief Operating Officer Dr.-Ing. Rolf Pfeiffer. The recovery of energy from process gases in not a new idea. "What is new, however, is that with our development, using a small, compact, decentralised energy recovery system, even small amounts of residual energy in the power range of 3 to 120 kilowatts can be converted into power". If the surplus energy potential is in the form of heat instead of pressure, it can only be utilised via a special closed circuit method - for example an ORC process (Organic Rankine Cycle). On this basis the three project partners developed an ORC test facility which has been installed and tested at the Centre for Energy Technologies at the University of Bayreuth.

In order to present their research findings, DEPRAG, together with the University of Bayreuth, organised a presentation for potential customers at the University of Bayreuth. At this event the participants had the unique opportunity of viewing the ORC system in action, getting to understand the processes and gaining further information about the integrated GET turbine generator.

The DEPRAG GET turbine generator

A compact unit consisting of a micro expansion turbine with electric generator generating power from gas. Without its electric control cabinet, the turbine generator is not much larger than a shoebox and can be installed in a decentralised position wherever gas is transferred from a higher to a lower pressure level. The pressure energy released by this shift is only utilised in the rarest situations and therefore valuable energy potential is being wasted.

The innovative GET turbine generator converts the energy contained in working fluid into power. Gas flows into the turbine, is "compressed" by jets, accelerated and releases energy. The kinetic energy is converted into electric energy in the generator. In this innovative system, the turbine and electric generator constitute a compact unit - they share a common shaft. Consequently: When the turbine turns, the rotor of the generator also turns.

The DEPRAG GET turbine generator is available in sizes 5 kW, 25 kW, 50 kW and 120 kW and is individually configured to each process requirement. It is necessary to define the specific processing parameters for the fluid mechanic layout and design of each turbine generator: type of medium, inlet pressure, outlet pressure, mass flow, inlet and outlet temperature. The specialists at DEPRAG also require a precise description of the application and processing conditions.

The GET turbine generator can be used in both open and closed processes. It can be designed for use with diverse mediums such as compressed air, natural gas, CO2, steam, cyclopentane, R245fa or SES36. In the ORC-test system in Bayreuth for example, cyclopentane is vaporised. Dr.-Ing. Rolf Pfeiffer: "Our energy recovery system is suitable for use in a multitude of applications to convert direct process gas into energy or by integrating our GET unit into an ORC process indirectly to utilise unused surplus heat

Multitude of application areas

Energy recovery using the DEPRAG turbine generator is appropriate for use in many application areas. When smelting metals, for example, aluminium or copper, the melting tanks are cooled by compressed air. The compressed air flows through cooling channels and absorbs heat. Normally, it is then released unused into the atmosphere. With the new micro expansion turbine and integrated generator this is changed into electricity and fed into the power network.

In biogas and combined heating and power units the GET turbine can also be utilised by a method based on the ORC process to convert residual energy into power. The electrical efficiency of systems can be successfully optimised by allowing small volumes of waste heat to be utilised economically in an ORC recovery process.

Essentially any combustion engine can be suitable for combination with a turbine. Even a very efficient combustion engine can use only around one third of the potential energy available from its fuel for mechanical activities. The remaining 60 percent of the energy generated is lost as waste heat in exhaust gases and cooling water. One strategy for mobile drives, for example in commercial vehicles, is to use this thermal energy via a vaporisation process. Here the turbine generator demonstrates one of its key features. Through recovered electrical power, the on-board electrical system can be powered, the dynamo is relieved and whole level of efficiency is improved.