It's the best kept secret of any barbeque: Who took all the time and effort to lovingly and carefully skewer each piece of food in place? Whose job is it in those popular restaurants where the guest expects high service and quality of presentation? In today's market where increasing costs of production are a deciding factor in the survival of every business, optimal use of resources is the best recipe for profit.

Automation and pre-processing can provide this. Not only fast, efficient machine processing of food must be achieved but also hygiene standards upheld. If the customer is to be more than just satisfied but also a big fan and even promoter of the business then the end product must be something special in itself.

MiVEG, a company which specialises in the manufacture of food processing machines and meat skewers. For their meat skewers, which they produce in-house, they rely on German beech wood. More than 4000 skewers are produced per hour by the semi-automatic equipment, piercing poultry, vegetables, cheese or meat. It is important that the final result still looks to the customer as good and thoughtfully made as a homemade product. "The wishes of the client come first", says Lars Kracker managerial associate of MiVEG, "therefore we work together with a manufacturer which specialises in dealing with individual requirements for each client's application. DEPRAG, a complete service provider for air motors, offers not only the motors but also a specially designed solution for each particular application.

Mini party skewers loaded with between 20g and a quarter of a kilo worth of food can therefore be cost-effectively produced. The wooden skewers can be from 10 centimetres up to 25 centimetres long. Within a few minutes the machine can be converted to other products because the cartridge can remove the skewers individually which means low wear and easily changeable parts. Therefore shorter conversion time is achieved and robust construction design for durability is provided. Lars Kracker: "We are very satisfied with the unconventionally fast reaction time of the DEPRAG engineers".

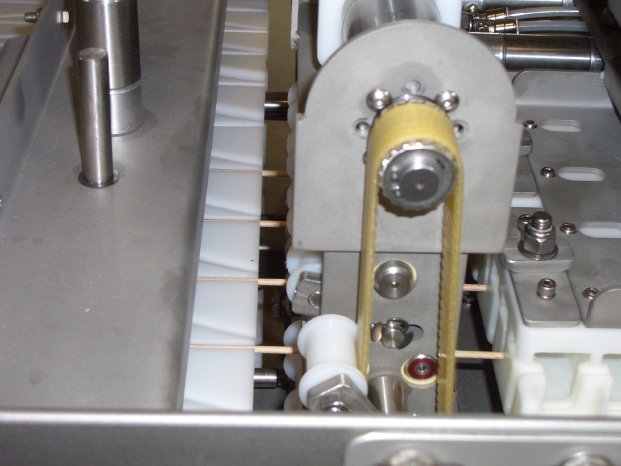

Attending to a customer's every needs is a matter of course for DEPRAG. Product manager Dagmar Hierl: "85% of all our projects are specially designed solutions. We offer individually specified standard motors, special motors or even fully automated production systems for all our customer's requirements, even for small quantities". The heavy work of the machine is done by the turning of the skewer unit which is powered by two air vane motors. In this unit the skewer is driven over two belts through the pieces of meat, onion and peppers.

Lars Kracker: "We chose the DEPRAG air motor drives because they are made from stainless steel". Because of the robust and sealed design of these drives they are ideal for application in moisture prone conditions and withstand cleaning with aggressive cleaning agents such as used in the food processing industry.

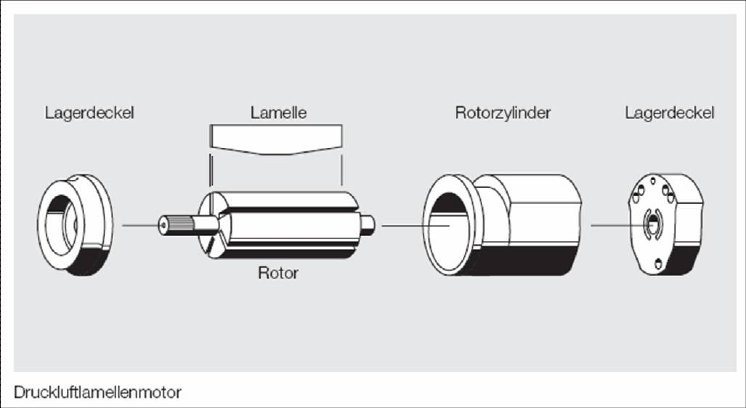

DEPRAG stainless steel motors' range of performance is between 20 W and 1.2 kW as standard design in speed range of up to 24,000 revolutions per minute. In special application cases such as in the food processing or chemicals industry, oil free operation when dry-running is possible. The air motors similar to steam machines put air under pressure and use the energy produced to drive the rotors in the tools. Vane motors consist essentially of a rotor which revolves in an eccentrically offset perforation of the rotor cylinder. (See diagram)

Because of this eccentrically offset perforation, the vanes form working chambers, the volume of which increases in the turn direction. In operation the centrifugal force of the vanes puts pressure on the wall of the cylinder and seals off the working chambers from each other. The pressure energy which develops is converted into kinetic energy. Through operation with air power the vane motors are overload safe and may be loaded to full standstill.

As well as the torque curve, the air motor offers "a fast and precise energy transmission. We apply pressure of 38kg onto the skewer therefore a powerful air motor with a compact form is ideal for our application", says Lars Kracker. In addition the air motor is temperature insensitive and cool in comparison to other drive systems under increased strain. The reason for this is the expansion and the following cooling of the air in the working chambers of the motor.