The enormously amplified and continually rising demands on the reliability and performance of parts and components also have an impact on component cleaning. This affects industries such as the semiconductor supply industry, electronics manufacturing, electric mobility, precision optics, the optoelectronic industry, sensor technology, photonics, thin-film technology, vacuum, laser and analysis technology, aerospace, and medical and pharmaceutical technology. In these industrial sectors, the term “high purity” is increasingly being used. “Despite the comparatively recent discussion about this area of application for industrial component cleaning, parts2clean has already taken it up through its exhibitors, who have a wide variety of solutions on offer,” explains Christoph Nowak, Project Director at Deutsche Messe. “Due to the growing importance of this field of expertise, we have decided for the first time to supplement the classic core areas of parts2clean with the highlight topic of High Purity.”

High purity, precision and ultra-fine cleaning

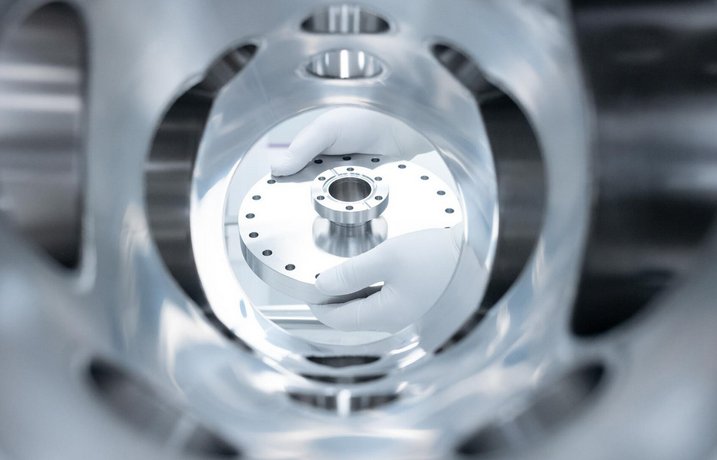

There is no generally applicable definition of the prerequisites and requirements that need to be met to achieve high-purity, precision and ultra-fine cleaning. These terms are therefore often used synonymously and also have a few things in common – basically, extremely high levels of particulate cleanliness, in some cases down to the nanometer range, and extremely stringent specifications with regard to residual film contamination. Those are the requirements. However, there are also differences. For example, high purity is often used in the context of the semiconductor industry and its suppliers, precision optics, aerospace, and other industries, where high-vacuum and ultra-high-vacuum environments are used to ensure specific properties of processes and end products. In addition to particulate and filmic-organic as well as inorganic contaminants, so-called hydrogen-induced outgassing (HIO) substances or elements must be taken into account here – not only for the component materials but also for the operating materials and cleaning media.

Not just a cleaning job

In high-purity, precision and ultra-fine cleaning, the aim is to remove even the tiniest amounts of dirt, which can vary depending on the industry and the component. This often involves ultra-fine particles and filmic contaminants, organics and/or inorganics, ionic residues or residues of microorganisms. The focus here is much more on the entire production chain than in the case of classic cleaning – for example, upstream machining processes must support the cleanliness objective, as well as cleanliness-compliant parts handling and the ambient conditions, for example, in a cleanroom.

In order to remove even the tiniest impurities, it is necessary for the equipment and cleaning technologies used – wet-chemical processes with solvents and aqueous media, dry cleaning with, for example, CO2 snow jets, plasma cleaning and vacuum bakeout systems – to be appropriately designed and constructed, and adapted to the specific cleanliness requirements of the components. In the case of wet-chemical processes, this also applies to the cleaning media and water qualities involved.

Another aspect involves the clean handling of the already cleaned parts. For this reason, the components are cleaned or discharged into a cleanroom in accordance with the applicable cleanliness specifications.

“High Purity” also a hot topic at international Expert Forum

“As the leading trade show for industrial component cleaning, we aim not only to be a reflection of the market, but also to drive the professional communication of tomorrow's topics,” emphasizes Christoph Nowak. “The topic of high purity will therefore be explored in greater depth in the bilingual Expert Forum.” The well-balanced program of this knowledge forum, which is organized jointly with the Fraunhofer Cleaning Business Unit and the Industrial Parts Cleaning Association (FiT), ensures that information on classic cleaning topics, current tasks and developments from a wide range of industrial sectors will not be neglected. These presentations by renowned speakers from science, research and industry will also be simultaneously translated (English German). “For national and international visitors, parts2clean thus enables a targeted transfer of knowledge about trends, innovations and benchmark applications in all areas of industrial parts cleaning,” reports Nowak.

Image source: VACOM Vakuum Komponenten & Messtechnik GmbH