With doks.gate, answering such questions becomes a breeze, even when faced with tight deadlines and large volumes. Thanks to AI-based 3D-measurement techniques, highresolution documentation cameras and innovative sensor technology, the system is able to generate meaningful data sets for each individual shipment. And it does so without any loss of time or additional manual effort. For this purpose, the doks.gate, consisting of an aluminum archway to which all hardware components are permanently attached, is mounted directly on the loading and unloading ramps or at junctions, such as fire doors or defined routes within the hall. The only thing left to do is to drive the shipments through the doks.gate.

For this purpose, any warehouse vehicles can be used, from simple pallet jacks to classic forklifts and driverless transport systems. Vehicles can pass through the doks.gate with speed up to 10 km/h. A camera system is used to recognize and read all labels attached to the shipment and to assign them to the corresponding data record so that it can be found immediately afterwards. In addition to high-resolution photographic documentation of any damage and the qualitative condition of the shipment, each data record also contains the recorded transport dimensions in length, width and height. This makes it possible to immediately check whether the transported shipments match the expected dimensions. If required, the system can also be equipped with sensors for temperature monitoring.

Stocktaking, localization and documentation in high-bay warehouses

Manually conducting stocktaking in a high-bay warehouse is often very time-consuming, ties up personnel resources, poses an occupational safety risk and hinders ongoing warehouse processes. Due to the monotonous nature of the task, it is extremely difficult to achieve precise counting results and the stock take results are inaccurate.

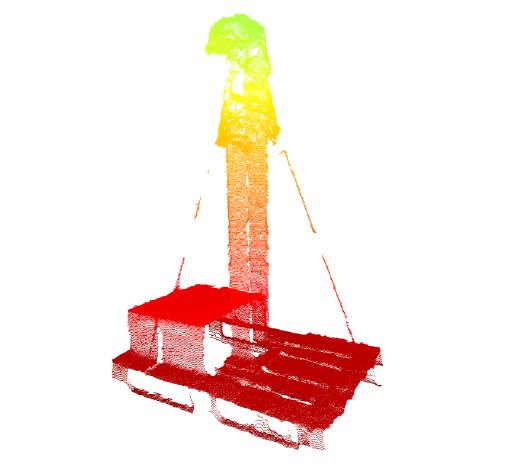

With doks.inventairy, the entire inventory process, from planning and execution to evaluation of the results, can be digitized and fully automated. An innovative system consisting of a drone and a ground vehicle is used for this purpose. This navigates autonomously through the warehouse and does not rely on GPS or other additional infrastructure in the warehouse.

With an average recording speed of 500 storage spaces per hour and an uninterrupted flight time of over five hours, the system can capture large storage areas with just one battery charge. doks.inventairy can be used both during ongoing warehouse operations and during closing times – thanks to the integrated LED lighting components, data capture is also possible in complete darkness. The sensors installed in both the drone and the ground vehicle take photos of each detected storage location and capture the labels attached to the stored objects. The recorded data sets for each storage location are visualized in a digital twin of the shelves. Empty storage locations are also displayed there. The results can be accessed in the doks.inventairy user interface or integrated directly into existing warehouse management systems via interfaces. If target inventory data is available, the system's digital comparison function can also be used. In this case, a comparison is made between the target data and the actual inventory data, and only the deviations are displayed to users. This reduces the effort required to check the counting results, to correct the data in the warehouse management system, and further accelerates the inventory process.

In addition to the application-specific features, the simple and fast integration of the system is a major advantage compared to other solutions. For the hardware and software integration, a few days are sufficient even for very large storage areas and apart from a power outlet, nothing is needed on site to collect data on the fly in a new warehouse in the shortest possible time.

Interested?

Visit us at booth 8A32 and get a personal impression of our innovative solutions.

We look forward to your visit!