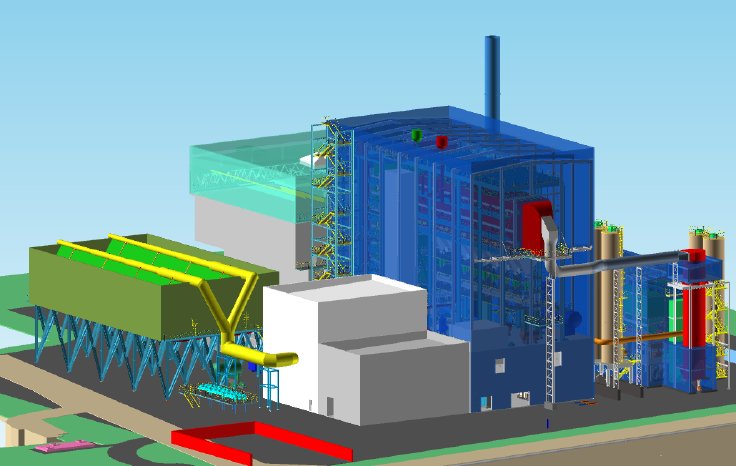

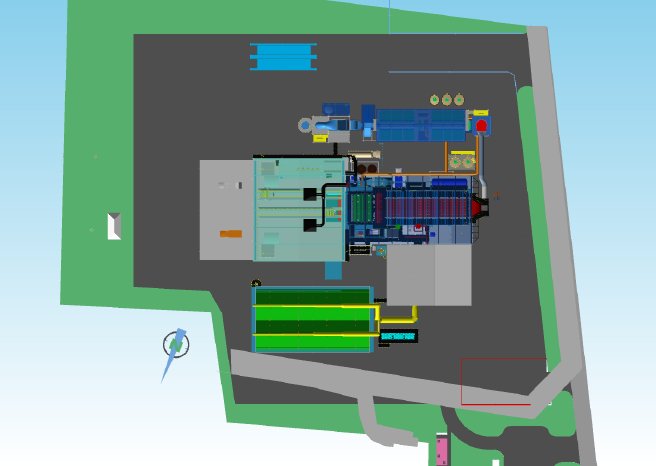

The new power plant will comprise one process line, including grate, boiler, and dry flue gas cleaning as well as water-steam cycle. The owner and operator will be MHKW Wiesbaden GmbH. After completion, the facility will thermally treat about 200,000 tonnes of municipal and commercial waste from the greater Wiesbaden area per year.

"We are pleased to be able to support our client in establishing safe and future-proof disposal capacities," says Gerhard Lohe, Director of Thermal Waste Treatment at Doosan Lentjes. "MHKW Wiesbaden GmbH benefits from our proven technologies, which enable reliable plant operation with high availability. At the same time, the processes can be flexibly adapted to changing fuel properties. Thus, even possible changes in the composition of the waste will not prevent the plant from reliably operating over its lifetime."

"Together with Doosan Lentjes, we are building one of the most modern plants in Europe on behalf of MHKW Wiesbaden GmbH. As ARIKON Hoch- und Ingenieurbau GmbH with its focus on industrial construction, the project is a great opportunity to bundle our competences together with Doosan Lentjes and to contribute to the establishment of modern environmental technologies in the field of energy generation," continues Ingo Habig, Managing Director of ARIKON Hoch- und Ingenieurbau GmbH.

In the overall technological process, the plant technology applied will produce electricity and district heating from the energy contained in the waste. The use of this energy, which is largely of biogenic origin, represents a sustainable alternative to burning fossil fuels. Thus, the MHKW will make an important contribution to saving climate-damaging CO2 emissions.

Wiesbaden will be the first project of this kind that Doosan Lentjes and ARIKON deliver together. The two companies have a long history of working together on various power plant projects outside the field of waste incineration. The results showed that customers can trust that they will receive a reliable solution tailored to their individual needs with an optimal cost-benefit ratio.

Doosan Lentjes is a specialist in thermal waste utilisation and supplies proprietary technologies along the entire value chain.