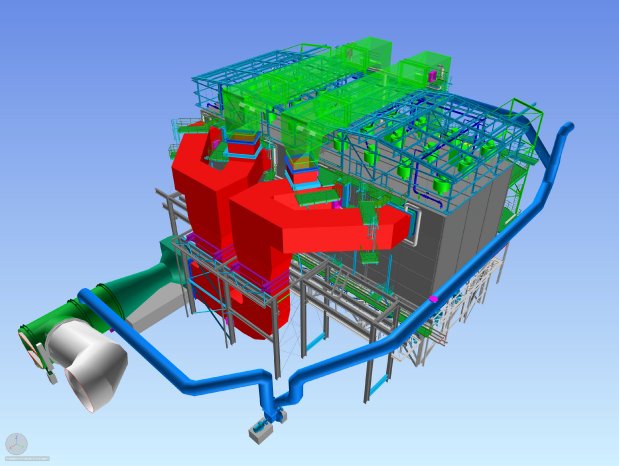

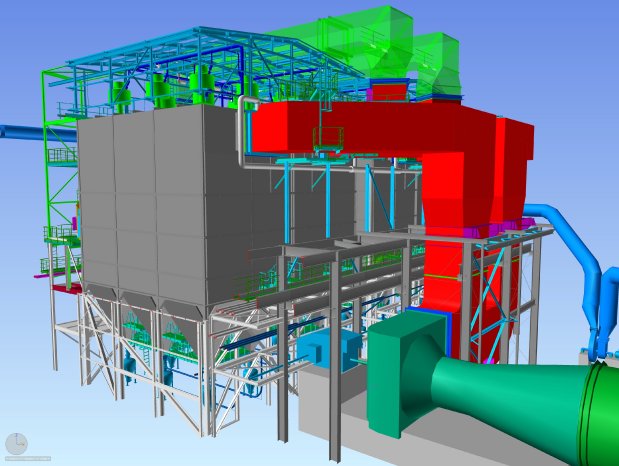

The current order includes the retrofit of boiler 2 of the 4x205 MWe power plant with a new low-pressure pulse-jet bag house filter.

Doosan Lentjes’ scope of work in the project will include the engineering, the delivery of key filter internals and the fly ash transport system. Completion is expected in the second half of 2021. An extended scope including plate work for filter, bypass heating system and a complete flue gas duct system is currently under discussion and will be awarded separately.

The new filter systems will remove solid particles from the flue gases and ensure full compliance with the relevant emissions legislation. The plant will thus help to reduce drastically the effects of dust emissions on human health. In addition, the retrofit measures will enable a more efficient fly ash transport, which will reduce the operation costs of the conveyors.

“The so far fruitful cooperation with Sev.en Energy is reflected in the second order we have now received from them in the last 12 months”, says Daniel Borke, Product Manager AQCS at Doosan Lentjes. “With this current project, we have further demonstrated our capabilities as a reliable and experienced partner for filter technology and further strengthened our position as a competent partner for large power plant projects in Eastern Europe.”

Frank Oberheid, Product Director AQCS at Doosan Lentjes, adds: “Decisive for our performance in Eastern Europe is our cooperation with our colleagues at Doosan Lentjes Czech. This not only strengthens our local presence, but also enables us to generate cost advantages that allow us to realize projects of this kind in an economically attractive framework.”

In August last year, Doosan Lentjes had received the order to equip the boilers 3&4 of the Chvaletice power plant with fabric filters. The project is currently under execution and expected to be completed and handed over to Sev.en Energy at the end of this year.