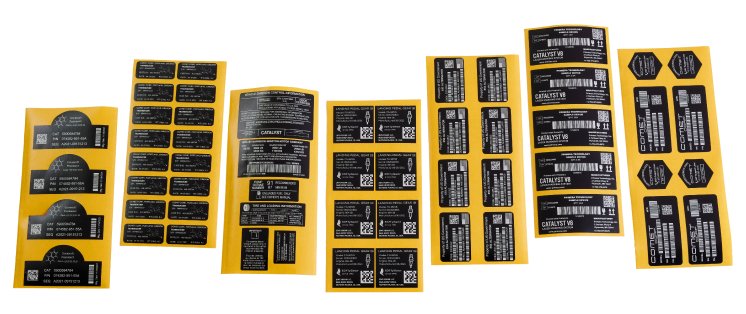

Catalyst allows fast and easy production of highly durable, synthetic labels for a wide range of rough-service applications. Labels produced with marking lasers, including Catalyst, are typically used to replace metal plates or far less durable labels produced by resin thermal transfer printers on polyester substrates.

Typical applications requiring such high-durability labels include UDI labels for medical devices and healthcare equipment, automobile VIN and under-hood part number, warning and instruction labels, aerospace and solar panel labels, serial tags for outdoor power equipment, vehicle and marine spare parts, building tools and materials, and much more.

Text, graphics, and linear or 2D/3D bar codes are laser-imaged onto Color Laser Film (“CLF”), developed and manufactured by Schreiner ProTech GmbH in Germany. CLF labels are explicitly designed for extreme environment applications and do not require extra lamination to withstand extended exposure to UV light, chemicals, liquids, and temperatures of up to 300°C.

Instead of ink, Catalyst uses a bundle of two, four, or eight fibre-coupled laser diodes along with matched, high precision lenses to image onto CLF. Bundled fiber lasers have never before been used in a roll-fed, desktop laser label imager, making Catalyst unique in its class. After imaging the CLF material, Catalyst’s built-in Digital Die-Cutting™ system cuts the labels to any shape, eliminating the need for pre-die-cut labels. Unlike other laser-based marking systems, it uses a knife blade instead of the laser beam to cut out the labels. This feature eliminates the need for a smoke and fume extraction system, saving even more money on the initial equipment costs and the ongoing costs of periodic filter changes, cleaning, and other maintenance.

Compared to Yag and CO2 lasers, Catalyst’s imaging method has several significant advantages for producing highly durable labels, including:

- Lower cost. Catalyst’s entry-level model’s price is just € 3,495 – about a tenth of the cost of machines with identical speed and imaging quality. Two faster versions are also available.

- Simple mechanics. Instead of a more traditional but more complex and expensive computer-controlled galvanometer with beam steering mirrors, Catalyst was designed more like a standard industrial label printer such as the LX910e Color Label Printer. This approach results in a far less complicated and more rugged machine with no special maintenance or ongoing calibration required.

- Ease of operation. Catalyst installs on a PC as a standard Windows printer. Any popular Windows-based label creation software can be used to send image files. No special operator training or certification is required.

A printer driver for Windows® 10+ is available online for download. Also available for download is an easy-to-use label design and printing software from Seagull Scientific called BarTender® 2021 UltraLite for Windows. Wired USB and Ethernet connectivity are standard.

Pricing and Availability

Three different models are available:

- Catalyst V2e: the entry-level model with two laser diodes – € 3,495 (MSRP)

- Catalyst V4e: four laser diodes for twice the speed of V2e – € 4,495 (MSRP)

- Catalyst V8e: eight laser diodes for twice the speed of V4e – € 6,495 (MSRP)

For more product information visit dtm-print.eu. Follow DTM print on Facebook at https://www.facebook.com/... and on Twitter at https://twitter.com/....