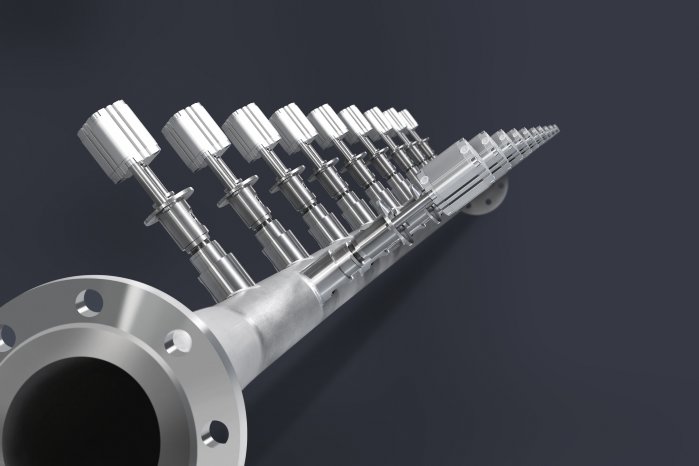

The technicians and engineers of this industry leading nozzle manufacturer have once again taken up the challenge of the market and implemented increasing demands for greater quality and reduced costs in the form of a new improved process. For the first time ever, the SCHLICK Blowline System features a completely homogeneous spray with the smallest possible droplet sizes. This spray optimization reduces glue consumption and prevents glue stains, as well as deposits in the blowline - meeting user requirements for quality and costs savings.

With a special design, SCHLICK nozzle experts have achieved an ideal balance between atomisation quality, drop speed, drop size distribution, volume flow density and flow rate. At the same time, simple handling and optimum operational reliability have been achieved. To cater for the requirements of manufacturers in the wood industry, the compact design and the use of only a few individual components enables simple assembly and dismantling. The system is suitable for a wide range of applications and can be used for water, glue, urea solution or hardener.

Thanks to integrated cleaning needles, blockage of the rust- and acid-resistant stainless steel (1.4404 / 1.4571) nozzles is almost impossible, even with high viscosity liquids in the orifice. The design complies with European Pressure Equipment Directive 97/23/EC. For several decades, Düsen-Schlick has supplied systems manufacturers and producers in the wood machining industry with process-optimised atomisation technology. The SCHLICK blowline system combines all the requirements for professional gluing and guarantees cost-effectiveness down to the last detail.