As a result, 9771 is now recorded in the approved materials database used by NASA and suppliers. The importance of this listing is that NASA has independently verified the coating to meet ASTM E595 and allows people looking for low outgassing materials to find the product more easily.

NASA low outgassing ASTM E595 test method is a screening procedure to determine the volatile content of materials when exposed to a vacuum environment. The test is run at 125°C (257°F) under a 5 X 10-5 Torr vacuum for 24 hours. The Total Mass Loss (TML %) and Collected Condensable Volatile Material (CVCM %) are measured. CVCM is of particular interest as it might be indicative of loss of electrical continuity, or some other effect caused by material being deposited where it is not intended.

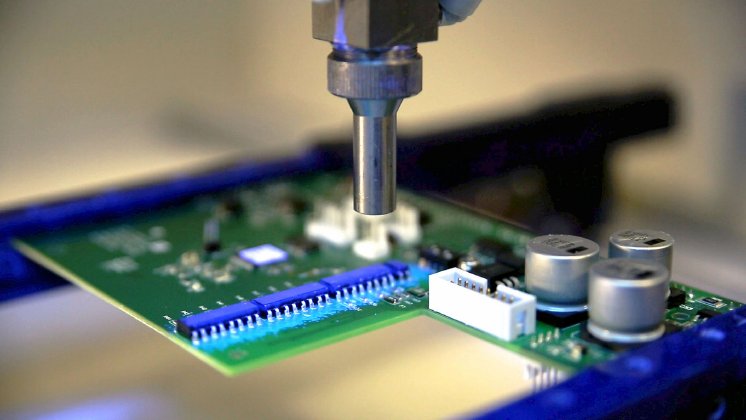

In conjunction with the NASA material number, dispense guidelines have been established to ensure that a consistent coating thickness of 50.8-101.6µm (0.002-0.004”) is achieved. Dymax recommends applying the conformal coating using a PVA Delta 6 Selective Coating/Dispense System with FCS300 series valve. The Dymax team of Applications Engineers are available to customers through every step of their project to ensure successful outcomes.

9771 is a reworkable conformal coating that cures with light and moisture to ensure material that flows underneath components on PCBs fully cures. The product has low ionic content compliance with MIL Std 883 Method 5011, UL 94 V0 flammability rating, and is UL 746E recognized.

For additional information on Dymax, visit www.dymax.com