Dual-cure 9771 is a reworkable coating that cures with light and moisture to ensure material that flows underneath components on PCBs fully cures. The product has low ionic content and meets low outgassing ASTM E595 for cleaner PCBs during extreme conditions and is certified to meet Mil-Std 883 Method 5011, a feature that no conformal coating chemistry on the market currently possesses. This coating has UL 94 V0 flammability rating and is UL 746E recognized.

NASA low outgassing ASTM E595 test method is a screening procedure to determine the volatile content of materials when exposed to a vacuum environment. The test is run at 125°C (257°F) under a 5 X 10-5 Torr vacuum for 24 hours. The Total Mass Loss (TML %) and Collected Condensable Volatile Material (CVCM %) are measured. CVCM is of particular interest as it might be indicative of loss of electrical continuity, or some other effect caused by material being deposited where it is not intended.

Mil-Std 883 method 5011 is a standard methods for procedures to test electronic devices for military and aerospace electronic systems. This standard includes mechanical and electrical tests to ensure quality and reliability suitable for intended end-uses that require low properties for ionic content, outgassing, conductivity, and pH. In addition, this includes environmental testing to determine the resistance to the detrimental/harmful effects of natural elements and conditions surrounding military and space operations.

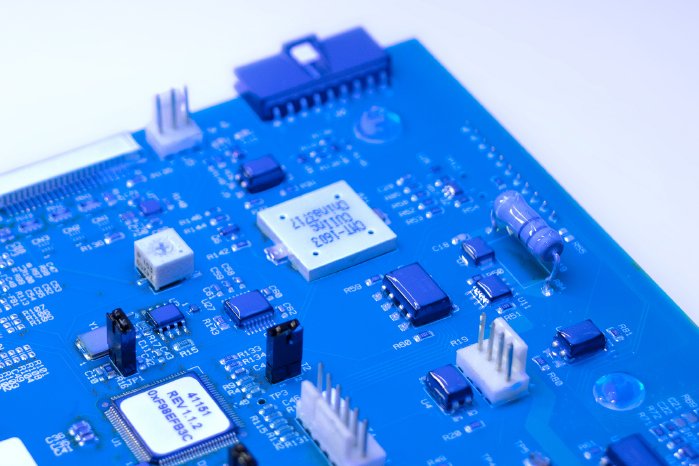

Other important features of 9771 include a resistance to corrosion, temperature, and humidity, coating thickness to 0.008” (0.20mm), and a bright blue fluorescing tracer that is highly visible on boards before and after cure for high-speed, inline quality inspection.

For additional information on Dymax, visit www.dymax.com