3M Glass Bubbles have already been successfully used for decades as additives for plastic applications, above all in vehicle components, because the small, uniform hollow microspheres can reduce the weight of plastic parts by up to 30 percent due to their low density. Beyond that, Glass Bubbles offer many advantages with regard to the processing and quality of the components.

15 percent lighter engine cover thanks to Glass Bubbles

A current application example shows that the use of 3M Glass Bubbles in the manufacture of engine covers can significantly reduce their weight. To achieve this, PENTAC Polymer GmbH replaced a portion of the fillers in a conventional glass fibre reinforced polyamide by Glass Bubbles. The result was that the weight of the cover was reduced by 15 percent. Due to the improved flow properties of the material and its shorter cooling time, it was possible to optimise the injection moulding process by 10 percent at the same time. As a result, BBP Kunststoffwerk Marbach Baier GmbH was able with the aid of PENTAC and 3M to manufacture the components virtually at similar costs.

Optimized polymer processing through additives

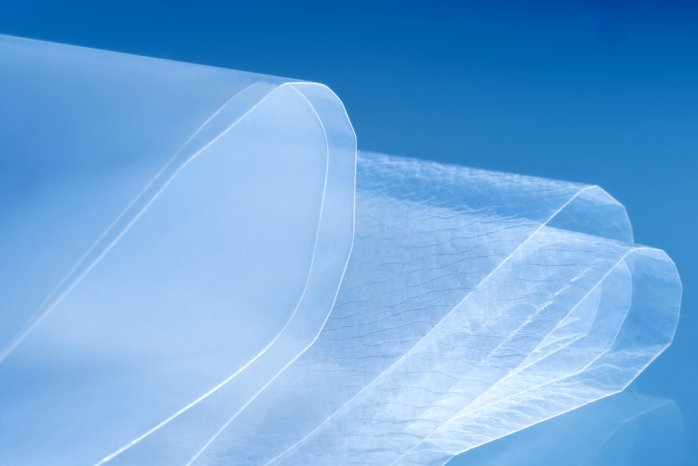

Another highlight at the fair will be the fluoropolymer based processing additives for plastics processing: 3M Dynamar Polymer Processing Additives (PPAs). These are admixed to the polymer production in the extrusion process to prevent process defects such as die-build up or interfacial instability (Shark-skin). Furthermore, PPAs help to reduce energy costs by reducing temperature and pressure and enable faster colour changes or a higher transparency of the film.

Fields of application are mainly multi-layer films, for example for the packaging industry. The most common use is for food packaging.

The high quality range of Dyneon GmbH's Fluoroelastomers, Fluorothermoplastics and PTFE product portfolio will also be presented at the fair in addition to the processing additives.

Visitors to the Fakuma can find out more about the products from 3M Advanced Materials at the 3M booth (Hall B4, booth 4406) and discuss solutions and process improvements in plastics processing with the experts.