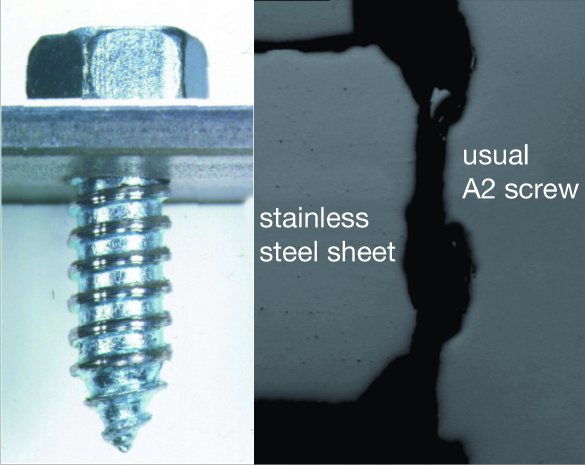

Laboratory tests show the strength of thread edges often does not suffice for a function-proof fastening. The reason is that while screwing, the thread edges are considerably deformed through the high-strength steel. Thus, a sufficient gearing with the engineering structure is not achieved. The consequence may be immense property damage or personal injury.

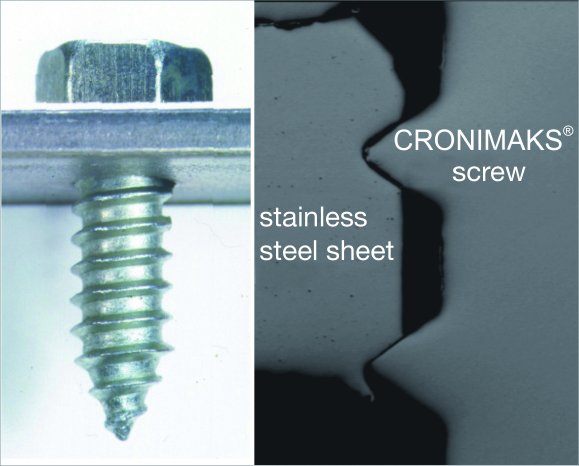

With the Cronimaks screw, EJOT has developed a solution for this kind of application. The self-tapping screw is made from austenitic stainless steel. Thanks to an innovative production process the thread edges achieve a particularly high edge strength.

Cut analyses of screwed construction parts prove the advantages of EJOT Cronimaks. They show that the screw accurately forms the internal screw thread. The thread edges remain intact.

In connection with the corrosion-proof design in stainless steel, this allows a function-proof fastening even in high-strength steels with all advantages offered by self-tapping screws.

- cost reduction due to unnecessary tapping

- fastening even in places to be reached from the outside only for greater design scope in the engineering structure (no lock nut necessary)

The EJOT Cronimaks is technically approved for the direct screwing of profiled plates and sandwich elements made from steel grade S355 (St 52-3). The Cronimaks may also be used in stainless steel with tensile strengths of up to 700 N/mm2 (German approvals Z-14.1-4 and Z-14.4-407).

Big principals are convinced by the performance of EJOT Cronimaks. Around 300.000 screws were installed in the largest production building of Scandinavia, the aluminium production plant of Norsk Hydro in More on Sunndalsora. Further sites are the multifunction arenas in Gelsenkirchen (Schalke) and in Dusseldorf.